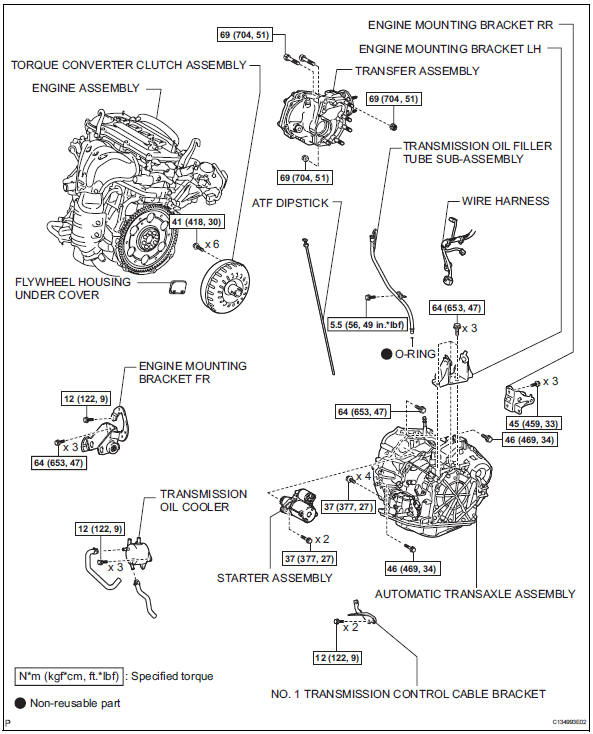

Toyota RAV4 (XA40) 2013-2018 Service Manual: Automatic transaxle assembly

Components

Removal

- Remove engine assembly with transaxle

- Remove the engine with transaxle (see page em- 98).

- Drain automatic transaxle fluid

- Remove the drain plug and gasket, and drain atf.

- Install a new gasket and the drain plug.

Torque: 47 n*m (479 kgf*cm, 35 ft.*Lbf)

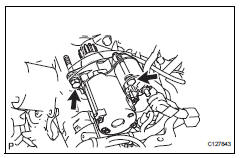

- Remove starter assembly

- Disconnect the starter connector.

- Open the terminal cap, and remove the nut and disconnect the starter wire.

- Remove the 2 bolts and starter.

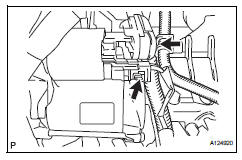

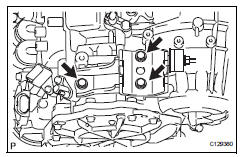

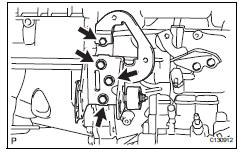

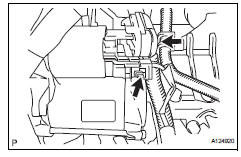

- Disconnect wire harness

- Disconnect the park/neutral position switch connector.

- Disconnect the transaxle wire connector.

- Disconnect the 2 speed sensor connectors.

- Disconnect the wire harness clamps.

- Remove transmission oil cooler

- Remove the oil cooler (see page ax-127).

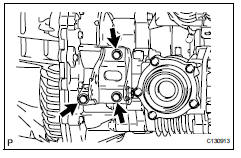

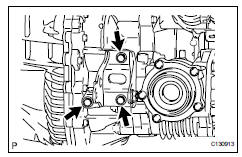

- Remove engine mounting bracket rr

- Remove the 3 bolts and mounting bracket.

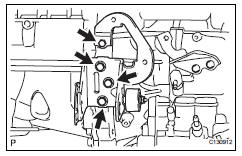

- Remove engine mounting bracket fr

- Remove the 4 bolts and mounting bracket.

- Remove engine mounting bracket lh

- Remove the 3 bolts and mounting bracket.

- Remove transfer assembly

- Remove the transfer (see page tf-59).

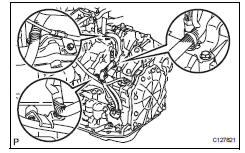

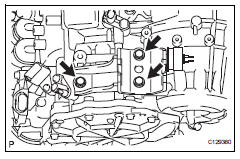

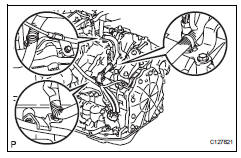

- Remove automatic transaxle assembly

- Remove the flywheel housing under cover

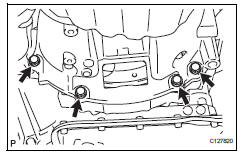

- Turn the crankshaft to gain access and remove the 6 bolts while holding the crankshaft pulley bolt with a wrench.

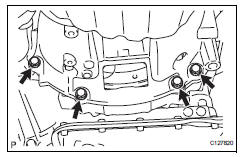

- Remove the 4 lower side mounting bolts.

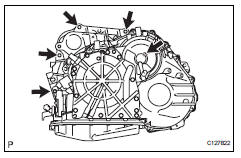

- Remove the 5 upper side mounting bolts.

- Separate and remove the automatic transaxle.

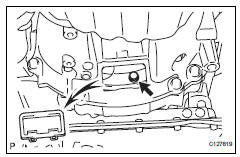

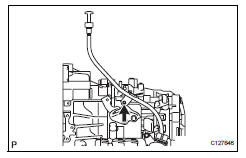

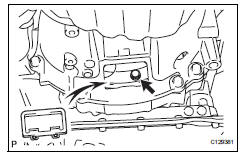

- Remove transmission oil filler tube subassembly

- Remove the atf dipstick.

- Remove the bolt and oil filler tube.

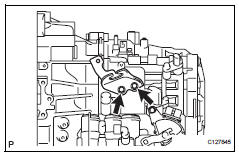

- Remove no. 1 Transmission control cable bracket

- Remove the 2 bolts and cable bracket.

- Remove torque converter clutch assembly

Installation

- Inspect torque converter clutch assembly

- Inspect the torque converter (see page ax-153).

- Install torque converter clutch assembly

- Install the torque converter clutch to the automatic transaxle.

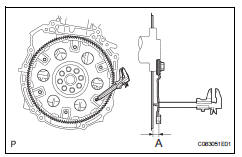

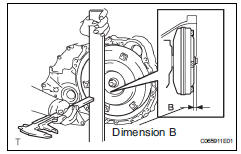

- Using a vernier caliper, measure dimension a between the transaxle and the end surface of the drive plate.

- Using a vernier caliper and straightedge, measure the dimension b shown in the illustration and check that b is greater than a.

Standard dimension: a + 1.0 Mm (0.039 In.) Or more

- Install no. 1 Transmission control cable bracket

- Install the cable bracket with the 2 bolts.

Torque: 12 n*m (122 kgf*cm, 9 ft.*Lbf)

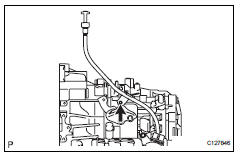

- Install transmission oil filler tube subassembly

- Install the filler tube with the bolt.

- Install the filler tube with the bolt.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*Lbf)

- Install the atf dipstick.

- Install automatic transaxle assembly

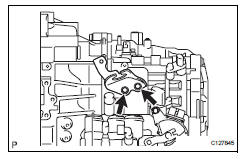

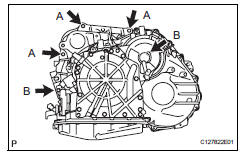

- Install the automatic transaxle with the 5 upper side mounting bolts to the engine.

Torque: 64 n*m (653 kgf*cm, 47 ft.*Lbf) for bolt a 46 n*m (469 kgf*cm, 34 ft.*Lbf) for bolt b

- Install the 4 lower side mounting bolts.

Torque: 37 n*m (377 kgf*cm, 27 ft.*Lbf)

- Install the 6 torque converter clutch mounting bolts.

Torque: 41 n*m (418 kgf*cm, 30 ft.*Lbf)

Hint:

First install the green colored bolt and then the 5 bolts.

- Install the flywheel housing under cover.

- Install transfer assembly

- Install the transfer (see page tf-75).

- Install engine mounting bracket lh

- Install the mounting bracket with the 3 bolts.

Torque: 64 n*m (653 kgf*cm, 47 ft.*Lbf)

- Install engine mounting bracket fr

- Install the mounting bracket with the 4 bolts.

Torque: 64 n*m (653 kgf*cm, 47 ft.*Lbf) for 14 mm head bolt

Torque: 12 n*m (122 kgf*cm, 9 ft.*Lbf) for 12 mm head bolt

- Install engine mounting bracket rr

- Install the mounting bracket with the 3 bolts.

Torque: 45 n*m (459 kgf*cm, 33 ft.*Lbf)

- Install transmission oil cooler

- Install the oil cooler (see page ax-127).

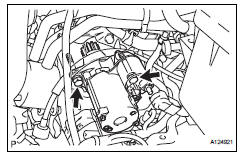

- Connect wire harness

- Connect the wire harness clamps.

- Connect the 2 speed sensor connectors.

- Connect the transaxle wire connector.

- Connect the park/neutral position switch connector.

- Install starter assembly

- Install the starter with the 2 bolts.

Torque: 37 n*m (377 kgf*cm, 27 ft.*Lbf)

- Connect the starter wire with the nut.

Torque: 13 n*m (133 kgf*cm, 10 ft.*Lbf)

- Connect the starter connector.

- Install the terminal nut and cover the nut with the

cap.

Torque: 9.8 N*m (100 kgf*cm, 7 in.*Lbf)

- Install engine assembly with transaxle

- Install the engine with transaxle. (See page em- 105).

- Add automatic transaxle fluid

Fluid type: toyota genuine atf ws

- Inspect automatic transaxle fluid

- Inspect the automatic transaxle fluid (see page ax- 102).

- Perform reset memory

- Perform the reset memory procedures (a/t initialization) (see page ax-18).

Differential oil seal

Differential oil seal

Components

Replacement

Replace transaxle housing oil seal lh

Drain the automatic transaxle fluid.

Remove the drain plug and gasket, and drain

atf.

Install a new gasket and ...

Torque converter and drive plate

Torque converter and drive plate

Inspection

Inspect torque converter clutch assembly

Inspect the one-way clutch.

Install sst to the inner race of the one-way

clutch.

Sst 09350-32014 (09351-32010)

Set sst s ...

Other materials:

On-vehicle inspection

Check steering pad assembly (vehicle not involved in collision and

airbag not deployed)

Perform a diagnostic system check (see page rs-

49).

With the steering pad (with airbag) installed on the

vehicle, perform a visual check:

check for cuts, cracks or discoloration on the

...

Brake pedal load sensing switch

Description

The brake pedal load sensing switch is turned on when the brake pedal is

depressed with force exceeding

a predetermined level.

The skid control ecu detects if the brake pedal is depressed or not via this

circuit.

Wiring diagram

Inspection procedure

Notice:

When repla ...

Ecm communication stop mode (2006/01- )

Description

Wiring diagram

Inspection procedure

Notice:

Turn the ignition switch off before measuring the resistances of the

main wire and branch

wire.

After the ignition switch is turned off, check that the key reminder

warning system and light

reminder warning system ...