Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation (2005/11-2006/01)

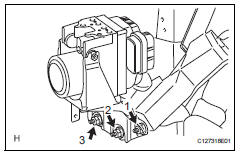

- Install abs and traction actuator assembly with bracket

Notice:

Do not remove the hole plug before connecting the brake tube. New actuators are filled with brake fluid.

- Install the actuator with bracket with the 3 nuts.

Torque: 19 n*m (194 kgf*cm, 14 ft.*Lbf)

Hint:

The nuts should be tightened in order from 1 to 3 as shown in the illustration.

Notice:

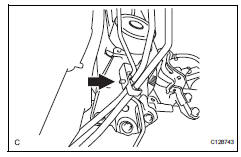

Be careful not to damage the brake tubes.

- Connect the brake tube clamp to the bracket.

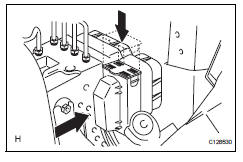

- Connect the connector and push the lock lever downward.

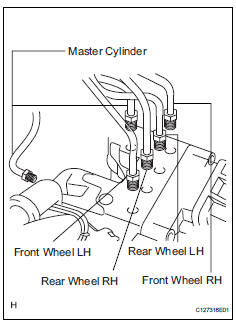

- Connect brake lines

- Using sst, connect the 6 brake lines to the correct locations on the actuator, as shown in the illustration.

Sst 09023-00101

Torque: 15.2 N*m (155 kgf*cm, 11 ft.*Lbf) without sst

14 N*m (144 kgf*cm, 10 ft.*Lbf) with sst

Hint:

Use a torque wrench with a fulcrum length of 30 cm (11.81 In.).

- Fill reservoir with brake fluid (see page br- 6)

- Bleed air from brake master cylinder (see page br-7)

- Bleed air from brake line (see page br-7)

- Bleed air from abs and traction actuator assembly (see page br-8)

- Check brake fluid level in reservoir (see page br-6)

- Check for brake fluid leakage

- Install air cleaner case sub-assembly

- Install the air cleaner case (see page em-105).

Hint:

Refer to the procedures from the installation of the air cleaner case up until the installation of the purge vsv.

- Connect cable to negative battery terminal

- Check abs and traction actuator assembly with intelligent tester

- Check the abs and traction actuator with the intelligent tester (see page bc-180).

Removal (2006/01- )

Removal (2006/01- )

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt preten ...

Front speed sensor

Front speed sensor

Components

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Ca ...

Other materials:

Vsc warning light remains on

Description

The skid control ecu is connected to the combination meter via the can

communication system.

W/o multi information display:

if the skid control ecu stores any dtcs which relate to the vsc system, the vsc

warning light comes on

in the combination meter.

W/ multi information d ...

Map light assembly

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove map light assembly

Detach the 4 cli ...

Identification information

Vehicle identification and serial numbers

Vehicle identification number

The vehicle identification number is stamped on the

vehicle identification number plate and on the

certification label, as shown in the illustrations.

Vehicle identification number plate

Certification label ...