Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation (2006/01- )

- Install front drive shaft assembly lh

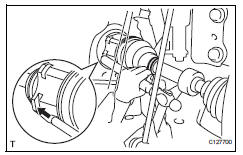

- Coat the spline of the inboard joint shaft with gear oil.

- Align the shaft splines and tap in the drive shaft with a brass bar and hammer.

Notice:

- Set the snap ring with the opening side facing downwards.

- Be careful not to damage the oil seal, boot and dust cover.

- Install front drive shaft assembly rh

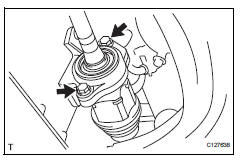

- Coat the spline of the inboard joint shaft with gear oil.

- Align the shaft splines and securely insert the drive shaft.

- Install the 2 bearing bracket bolts.

Torque: 63.7 N*m (650 kgf*cm, 47 ft.*Lbf)

Notice:

Do not damage the oil seal, boot and dust cover.

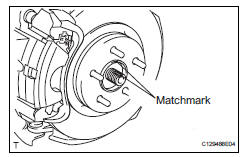

- Connect steering knuckle with axle hub lh

- Align the shaft splines in the drive shaft to the steering knuckle with axle hub, and connect the steering knuckle with axle hub.

- Connect steering knuckle with axle hub rh

Hint:

Use the same procedures described for the lh side.

- Connect front suspension no. 1 Lower arm sub-assembly lh (see page sp-24)

- Connect front suspension no. 1 Lower arm sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Install front stabilizer link assembly lh (see page sp-31)

- Install front stabilizer link assembly rh

Hint:

Use the same procedures described for the lh side.

- Connect tie rod end sub-assembly lh (see page ps-45)

- Connect tie rod end sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Connect front speed sensor lh

- Connect the speed sensor (see page bc-193).

- Install front speed sensor rh

Hint:

Use the same procedures described for the lh side.

- Install front axle hub nut (see page ah-11)

- Install front wheel torque: 103 n*m (1,050 kgf*cm, 76 ft.*Lbf)

- Add automatic transaxle fluid

- Add automatic transaxle fluid for u140f (see page ax-152).

- Add automatic transaxle fluid for u241e (see page ax-151).

- Add automatic transaxle fluid for u151e (see page ax-177).

- Check for automatic transaxle oil leakage

- Inspect and adjust front wheel alignment

- Inspect and adjust the front wheel alignment (see page sp-3).

Installation (2005/11-2006/01)

Installation (2005/11-2006/01)

Install front drive shaft assembly lh

Coat the spline of the inboard joint shaft with gear

oil.

Using a brass bar and hammer, align the shaft

splines in the drive shaft.

Notice:

...

Front drive shaft assembly (for 4wd)

Front drive shaft assembly (for 4wd)

Components (2005/11-2006/01)

Components (2006/01- )

...

Other materials:

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Re ...

Removal

Drain differential oil

Remove rear wheel

Remove tailpipe assembly

Remove the tailpipe (see page ex-2).

Remove center exhaust pipe assembly

Remove the center pipe (see page ex-2).

Remove propeller with center bearing

shaft assembly (see page pr-3)

Remove rear suspen ...

Disassembly

Caution:

Wear protective gloves. Sharp areas on the seatback

frame, seat cushion frame and reclining adjuster may

injure your hands.

Remove rear seat headrest assembly

Remove rear seat center headrest

assembly

Remove center armrest hinge cover rh

Return the seatback to the upr ...