Toyota RAV4 (XA40) 2013-2018 Service Manual: Trouble in passenger airbag on / off indicator

Description

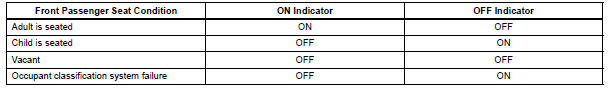

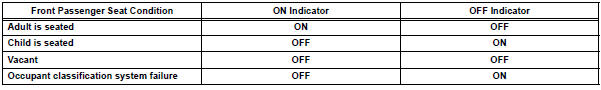

The occupant classification system detects the front passenger seat condition and then indicates whether the front passenger airbag is activated or not through the passenger airbag on / off indicator illumination.

The passenger airbag on / off indicator illumination changes depending on the front passenger seat condition as shown in the table below.

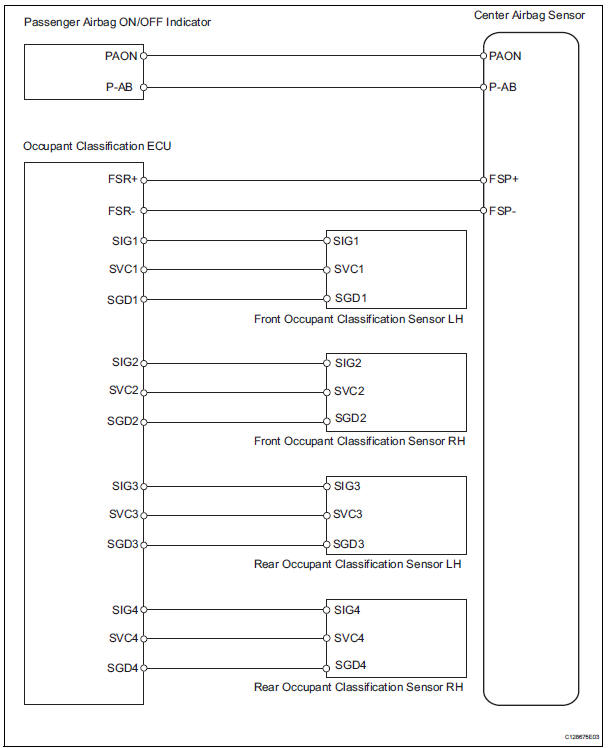

Wiring diagram

Inspection procedure

- Check srs warning light

- Turn the ignition switch on, and check the srs warning light condition.

Ok: the srs warning light does not come on.

- Check passenger airbag on/off indicator condition

- Turn the ignition switch on.

- Check if the passenger airbag on / off indicator correctly indicates the front passenger seat condition.

Ok

- Perform zero point calibration

- Turn the ignition switch off.

- Connect the intelligent tester (with can vim) to the dlc3.

- Turn the ignition switch on.

- Using the intelligent tester, perform the zero point calibration (see page rs-241).

Ok: completed is displayed.

- Perform sensitivity check

- Using the intelligent tester, perform the sensitivity check (see page rs-241).

Standard value: 27 to 33 kg (59.52 To 72.75 Lb)

End

- Retighten front seat assembly rh bolt

- Turn the ignition switch off.

- Loosen the 4 installation bolts of the front seat rh.

- Tighten the 4 installation bolts of the front seat rh to the specified torque (see page se-22).

Torque: 37 n*m{ 377 kgf*cm , 27 ft.*Lbf }

- Perform zero point calibration

- Connect the intelligent tester (with can vim) to the dlc3.

- Turn the ignition switch on.

- Using the intelligent tester, perform the zero point calibration (see page rs-241).

Ok: completed is displayed.

- Perform sensitivity check

- Using the intelligent tester, perform the sensitivity check (see page rs-241).

Standard value: 27 to 33 kg (59.52 To 72.75 Lb)

- Check connector

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Check that the connectors are properly connected to the occupant classification ecu and the 4 occupant classification sensors.

Ok: the connectors are connected.

- Disconnect the connectors from the occupant classification ecu and the 4 occupant classification sensors.

- Check that the connectors are not damaged or deformed.

Ok: the connectors are normal.

- Check for dtc

- Connect the connectors to the occupant classification ecu and the 4 occupant classification sensors.

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Turn the ignition switch on, and wait for at least 60 seconds.

- Turn the ignition switch off.

- Clear the dtcs (see page rs-249).

- Turn the ignition switch on, and wait for at least 60 seconds.

- Check the dtcs (see page rs-249).

Ok: dtc is not output.

- Replace occupant classification ecu

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Replace the occupant classification ecu (see page rs- 392).

Hint:

Perform the inspection using parts from a normal vehicle if possible.

- Perform zero point calibration

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Connect the intelligent tester (with can vim) to the dlc3.

- Turn the ignition switch on.

- Using the intelligent tester, perform the zero point calibration (see page rs-241).

Ok: completed is displayed.

- Perform sensitivity check

- Using the intelligent tester, perform the sensitivity check (see page rs-241).

Standard value: 27 to 33 kg (59.52 To 72.75 Lb)

End

Sleep operation failure of occupant classification ecu

Sleep operation failure of occupant classification ecu

Description

During sleep mode, the occupant classification ecu reads the condition of

each sensor while the ignition

switch is off.

In this mode, if the occupant classification ecu detects ...

Steering pad

Steering pad

Components

...

Other materials:

Headlight (hi-beam) circuit

Description

The body ecu controls the headlight relay, no. 2 Daytime running light relay

(marking: drl no. 2) And

no. 4 Daytime running light relay (marking: drl no. 4).

Wiring diagram

Inspection procedure

Perform active test by intelligent tester

Connect the intelligent test ...

Disassembly

Remove generator pulley with clutch

Remove the cap from the pulley.

Using a screwdriver, puncture the center of the

cap and pry it off.

Notice:

Do not reuse the cap.

Install sst to the pulley and vise as shown in the

illustration.

Sst 09820-63020

Mount sst (a) i ...

Wireless charger (if

equipped)

A portable device can be

charged by just placing Qi standard

wireless charge compatible

portable devices according to

the Wireless Power Consortium,

such as smartphones and

mobile batteries, etc., on the

charge area.

This function cannot be used

with portable devices that are

larger than the chargi ...