Toyota RAV4 (XA40) 2013-2018 Service Manual: Calibration

- Description

- After replacing components relating to the vsc or performing "front wheel alignment adjustment", clear and read the sensor calibration data.

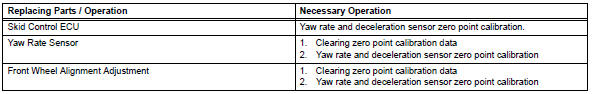

- Follow the chart to perform calibration.

- Clear zero point calibration data (when using intelligent tester)

- Clear the zero point calibration data.

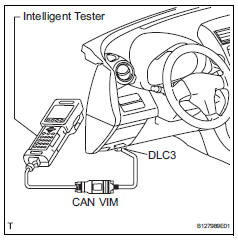

- Connect the intelligent tester (with can vim) to the dlc3.

- Turn the ignition switch on.

- Operate the intelligent tester to erase the codes (select "reset memory").

Hint:

Refer to the intelligent tester operator's manual for further details.

- Using the intelligent tester, perform the zero point calibration of the yaw rate and deceleration sensor.

Caution:

If the ignition switch is turned on for more than 15 seconds with the shift lever in the p position after zero point of the yaw rate and acceleration sensor has been cleared, only the zero point of the yaw rate sensor will be stored. If the vehicle is driven under this condition, the skid control ecu will recognize that zero point calibration of the acceleration sensor is not completed and will indicate that there is a malfunction in the vsc system using the indicator light.

- Preform zero point calibration of yaw rate and deceleration sensor (when using intelligent tester)

Notice:

- While obtaining the zero point, do not vibrate the vehicle by tilting, moving or shaking it and keep it stationary. (Do not start the engine.)

- Perform this on a level surface (with an inclination of less than 1°).

- Procedures for test mode.

- Check that the shift lever is in the p position and apply the parking brake.

Notice:

Dtcs c1210/36 and c1336/39 will be recorded if the shift lever is not the p position (see page bc-88).

- Connect the intelligent tester (with can vim) to the dlc3.

- Turn the ignition switch on.

- Set the intelligent tester to test mode (select "test mode").

Hint:

Refer to the intelligent tester operator's manual for further details.

- Obtain the zero point of the yaw rate and deceleration sensor.

- Keep the vehicle stationary on a level surface for 2 seconds or more.

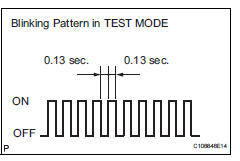

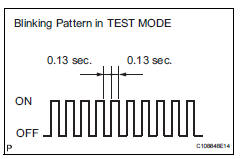

- Check that the vsc warning light blinks as shown in the illustration.

Hint:

- If the vsc warning light does not blink, perform the zero point calibration again.

- The zero point calibration is performed only once after the system enters test mode.

- Calibration cannot be performed again until the stored data is cleared once.

- Turn the ignition switch off.

- Clear zero point calibration data (when not using intelligent tester)

- Clear the zero point calibration data.

- Turn the ignition switch on.

- The warning light and indicator light come on for 3 seconds to indicate that the initial check is completed.

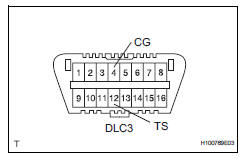

- Using sst, connect and disconnect terminals 12 (ts) and 4 (cg) of the dlc3 4 times or more within 8 seconds.

Sst 09843-18040

- Check that the vsc warning light comes on.

- Remove sst from the terminals of the dlc3.

- Using a check wire, perform the zero point calibration of the yaw rate and deceleration sensor.

Caution:

If the ignition switch is turned on for more than 15 seconds with the shift lever in the p position after zero point of the yaw rate and acceleration sensor has been cleared, only the zero point of the yaw rate sensor will be stored. If the vehicle is driven under this condition, the skid control ecu will recognize that zero point calibration of the acceleration sensor is not completed and will indicate that there is a malfunction in the vsc system using the indicator light.

- Perform zero point calibration of yaw rate and deceleration sensor (when not using intelligent tester)

Notice:

- While obtaining the zero point, do not vibrate the vehicle by tilting, moving or shaking it and keep it stationary. (Do not start the engine.)

- Perform this on a level surface (with an inclination of less than 1°).

- Procedures for test mode.

- Turn the ignition switch off

- Using sst, connect terminals 12 (ts) and 4 (cg) of the dlc3.

Sst 09843-18040

- Check that the shift lever is in the p position and apply the parking brake.

Notice:

Dtcs c1210/36 and c1336/39 will be recorded if the shift lever is not the p position (see page bc-88).

- Obtain the zero point of the yaw rate and deceleration sensor.

- Turn the ignition switch on.

- Keep the vehicle stationary on a level surface for 2 seconds or more.

- Check that the vsc warning light blinks as shown in the illustration.

Hint:

- If the vsc warning light does not blink, perform the zero point calibration again.

- The zero point calibration is performed only once after the system enters test mode.

- Calibration cannot be performed again until the stored data is cleared once.

- Turn the ignition switch off.

Check for intermittent problems

Check for intermittent problems

Check for intermittent problems

Hint:

A momentary interruption (open circuit) in the connectors

and/or wire harness between the sensors and ecus can

be detected by using the ecu data list fun ...

Test mode procedure

Test mode procedure

Hint:

By switching the skid control ecu from normal mode to

test mode, abnormality detection sensitivity is enhanced

and troubleshooting can be conducted efficiently.

Perform a sensor check ...

Other materials:

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Re ...

Transmitter id

Description

Hint:

It is necessary to perform the procedure to identify the tire pressure

monitor valve that is malfunctioning

because it cannot be identified by the output dtc.

Inspection procedure

Notice:

It is necessary to register an id code after replacing the tire pressure

wa ...

How to proceed with troubleshooting

Hint:

*: Use the intelligent tester.

Hint:

If the display indicates a communication fault in the tester,

inspect the dlc3.

Hint:

Record or print dtcs and freeze frame data, if necessary.

Hint:

If the engine does not start, first perform the "check dtc"

procedures a ...