Toyota RAV4 (XA40) 2013-2018 Service Manual: Disassembly

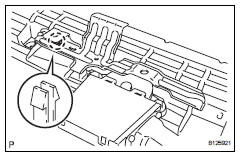

- Remove sliding roof drive gear subassembly

- Remove the claw and room light bracket.

- Remove the 2 bolts and drive gear.

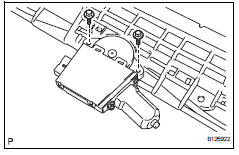

- Remove sliding roof drain hose joint lh

- Remove the screw and joint.

- Remove sliding roof drain hose joint rh

Hint:

Use the same procedures described for the lh side.

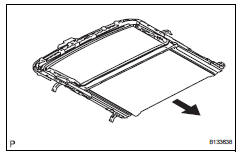

- Remove sunshade trim sub-assembly

- Slide and remove the sunshade trim sub-assembly.

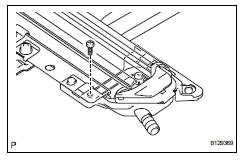

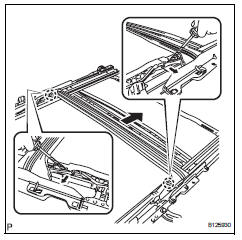

- Remove sliding roof drive cable

Notice:

Do not disassemble the sliding roof drive cable subassembly except when replacing it.

- Remove the 2 screws and 2 sliding roof side stoppers.

- Using a screwdriver, detach the 2 claws. Then slide the drip channel rearward to remove it.

Hint:

Tape the screwdriver tip before use.

- Using a screwdriver, slide the drive cables backward and remove them.

Hint:

- Tape the screwdriver tip before use.

Removal (2006/01- )

Removal (2006/01- )

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt preten ...

Reassembly

Reassembly

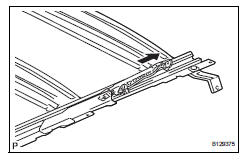

Install sliding roof drive cable

Using a screwdriver, slide the sliding roof drive

cable sub-assemblies in the direction indicated by

the arrow in the illustration to install them.

...

Other materials:

For vehicles equipped with vehicle stability (vsc) system

Notices when using drum tester

Before beginning testing, disable the vsc. To

disable the vsc, turn the ignition switch off

and connect sst to terminals 12 (ts) and 4

(cg) of the dlc3.

Sst 09843-18040

Notice:

Confirm that the vsc warning light blinks.

Vsc system will be r ...

Cleaning the Digital Rearview

Mirror

â– Cleaning the mirror surface

If the mirror surface is dirty, the

image on the display may be difficult

to see.

Clean the mirror surface gently

using a soft dry cloth.

â– Cleaning the camera

If the camera lens is dirty, the

displayed image may not be

clear. In this case, clean it with a

soft clo ...

Gauges and meters (with 12.3-inch multi-information display)

The meters display various drive information.

Meter display

â– Locations of gauges and meters

The meter type can be changed on

of the multi-information display.

Type 1/Type 2

The units of measure may differ depending on the intended destination of

the vehicle.

Multi-information display

Presen ...