Toyota RAV4 (XA40) 2013-2018 Service Manual: Freeze frame data

- Description

Freeze frame data records the engine conditions (fuel system, calculated load, engine coolant temperature, fuel trim, engine speed, vehicle speed, etc.) When a malfunction is detected. When troubleshooting, it can help determine if the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

Hint:

If it is impossible to duplicate the problem even though a dtc is detected, confirm the freeze frame data.

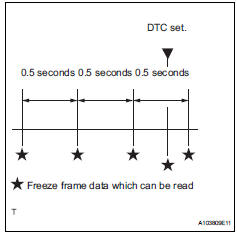

The ecm records engine conditions in the form of freeze frame data every 0.5 Seconds. Using the intelligent tester, 5 separate sets of freeze frame data can be checked.

- 3 Data sets before the dtc was set.

- 1 Data set when the dtc was set.

- 1 Data set after the dtc was set.

These data sets can be used to simulate the condition of the vehicle around the time of the occurrence of the malfunction. The data may assist in identifying the cause of the malfunction, and in judging whether it was temporary or not.

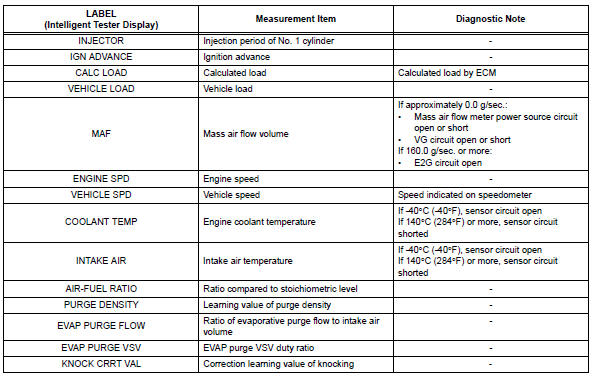

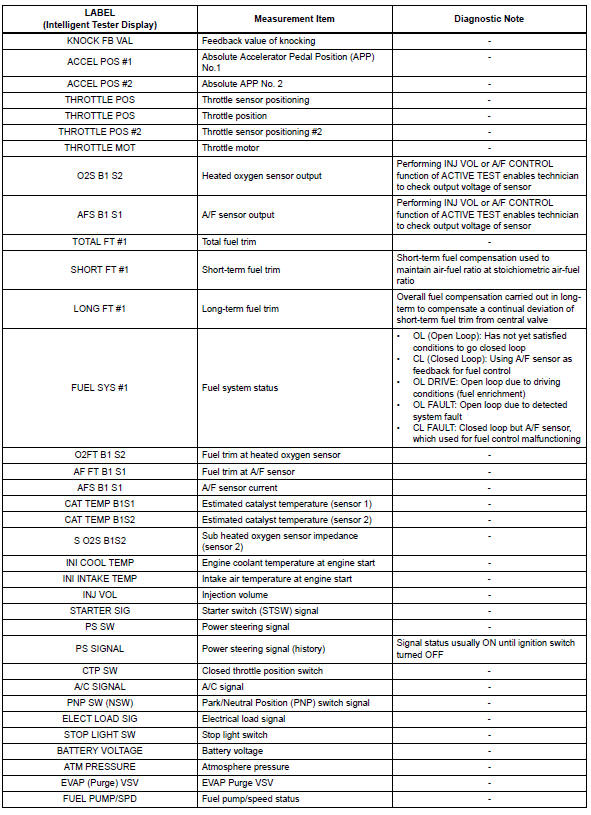

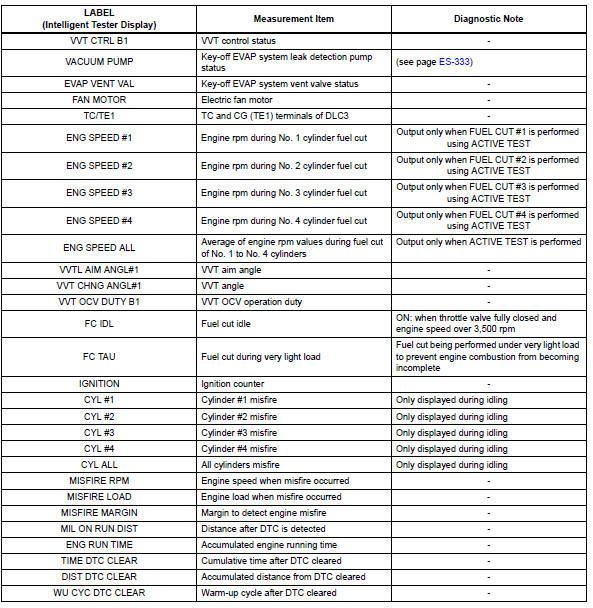

- List of freeze frame data

Dtc check / clear

Dtc check / clear

Notice:

When the diagnosis system is changed from normal

mode to check mode or vice versa, all dtcs and freeze

frame data recorded in normal mode are erased. Before

changing modes, always check an ...

Check mode procedure

Check mode procedure

Hint:

Intelligent tester only:

compared to normal mode, check mode is more sensitive to

malfunctions. Therefore, check mode can detect the

malfunctions that cannot be detected by normal mode.

Not ...

Other materials:

Maintenance requirements

To ensure safe and economical

driving, day-to-day care

and regular maintenance

are essential. It is the

owner's responsibility to

perform regular checks.

Toyota recommends the following

maintenance:

ÔľáRepair and replacement

It is recommended that genuine

Toyota parts be used for repairs to

ensure ...

Disassembly

Inspect oil pump assembly (see page ax-218)

Remove clutch drum oil seal ring

Remove the 2 clutch drum oil seal rings.

Remove stator shaft assembly

Using a t30 ''torx'' socket, remove the 11 bolts and

stator shaft. Keep the gears in assembling order.

Inspect clearan ...

Using the ÔÇťsetupÔÇŁ menu (ÔÇťbluetooth*ÔÇŁ menu)

Registering a bluetooth® device in the system allows the system

to function. The following functions can be used for registered

devices:

Functions and operation procedures

Press the ÔÇťsetupÔÇŁ button and select ÔÇťbluetooth*ÔÇŁ using the

ÔÇťtuneÔÇóscrollÔÇŁ knob.

Press the knob and sele ...