Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation

Hint:

- Use the same procedures for the lh side and rh side.

- The procedures listed below are for the lh side.

- A bolt without a torque specification is shown in the standard bolt chart (see page ss-2).

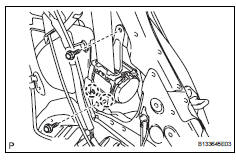

- Install rear no. 1 Seat outer belt assembly lh

- Align the claws with the seat belt positioning holes, and install the retractor of the seat belt with the 2 bolts as shown in the illustration.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*Lbf) for upper bolt

42 N*m (428 kgf*cm, 31 ft.*Lbf) for lower bolt

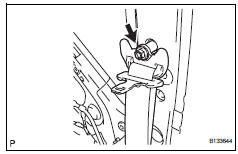

- Connect the shoulder anchor with the bolt.

Torque: 42 n*m (428 kgf*cm, 31 ft.*Lbf)

- Install inner roof side garnish assembly lh (w/ rear no. 2 Seat) (see page ir-52)

- Install rear no. 2 Seat outer belt assembly lh (w/ rear no. 2 Seat)

- Align the claws with the seat belt positioning holes and install the retractor of the seat belt with the 2 bolts as shown in the illustration.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*Lbf) for upper bolt

42 N*m (428 kgf*cm, 31 ft.*Lbf) for lower bolt

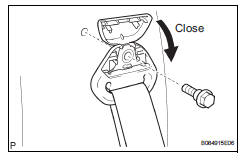

- Connect the shoulder anchor with the bolt.

Torque: 42 n*m (428 kgf*cm, 31 ft.*Lbf)

- Close the cover cap.

- Install inner roof side garnish assembly lh (w/o rear no. 2 Seat) (see page ir-51)

- Install deck trim side panel assembly lh (w/ rear no. 2 Seat) (see page ir-53)

- Install deck trim side panel assembly lh (w/ o rear no. 2 Seat) (see page ir-52)

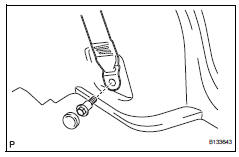

- Connect rear no. 2 Seat outer belt assembly lh (w/ rear no. 2 Seat)

- Connect the seat belt's floor anchor with the bolt.

Torque: 42 n*m (428 kgf*cm, 31 ft.*Lbf)

- Close the cover.

- Connect rear no. 1 Seat outer belt assembly lh

- Connect the seat belt's floor anchor with the bolt.

Torque: 42 n*m (428 kgf*cm, 31 ft.*Lbf)

- Attach the lap belt outer anchor cover.

- Install reclining remote control lever bezel lh (w/o rear no. 2 Seat)

- Install rear floor finish plate (see page ir- 55)

- Install rear no. 1 Floor mat support side plate (see page ir-55)

- Install rear floor no. 3 Board

- Install rear floor no. 2 Board

- Install rear no. 2 Seat assembly lh (w/ rear no. 2 Seat) (see page se-121)

- Install rear no. 2 Seat assembly rh (w/ rear no. 2 Seat) (see page ir-55)

- Install no. 2 Seat leg cover lh (w/ rear no. 2 Seat) (see page se-123)

- Install no. 2 Seat leg cover rh (w/ rear no. 2 Seat) (see page ir-56)

- Install no. 2 Seat hinge cover lh (w/ rear no.

2 Seat) (see page se-123)

- Remove no. 2 Seat hinge cover rh (w/ rear no.

2 Seat) (see page ir-56)

- Install deck board assembly (w/o rear no. 2 Seat)

- Install rear floor no. 1 Board (w/o rear no.

2 Seat)

- Install tonneau cover assembly (w/o rear no. 2 Seat)

- Install package tray trim pocket subassembly (w/o rear no. 2 Seat)

- Install rear door opening trim weatherstrip lh

- Install rear door scuff plate lh (see page ir-57)

- Connect cable to negative battery terminal

Removal

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 ...

Rear center seat outer belt assembly

Rear center seat outer belt assembly

Components

Removal

Caution:

Wait at least 90 seconds after disconnecting the cable

from the negative (-) battery terminal to prevent airbag

and seat be ...

Other materials:

Rear shock absorber

Components

Removal

Hint

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove rear wheel

Remove rear shock absorber assembly lh

Support the no. 2 Suspension arm lh with a jack.

Notice:

Place a wooden or rubber b ...

Driving mode select switch

The driving modes can be

selected to suit the driving

and usage conditions.

Selecting a driving mode

â– FF vehicles/Dynamic

Torque Control AWD vehicles

Eco drive mode

Suitable for driving to improve fuel

economy by more smoothly generating

torque in response to accelerator

pedal operations comp ...

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

When removing the moulding, heat the vehicle body and

moulding using a heat light.

Standard heating temperature

Notice:

Do not heat the vehicle body and moulding

excessively.

...