Toyota RAV4 (XA40) 2013-2018 Service Manual: Removal

Hint:

- Use the same procedures for the rh side and lh side.

- The procedures listed below are for the lh side.

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

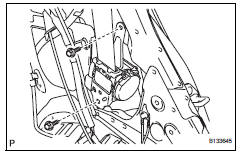

- Remove rear door scuff plate lh (see page ir-26)

- Remove rear door opening trim weatherstrip lh

- Remove package tray trim pocket subassembly (w/o rear no. 2 Seat)

- Remove tonneau cover assembly (w/o rear no. 2 Seat)

- Remove rear floor no. 1 Board (w/o rear no.

2 Seat)

- Remove deck board assembly (w/o rear no. 2 Seat)

- Remove no. 2 Seat hinge cover lh (w/ rear no.

2 Seat) (see page se-109)

- Remove no. 2 Seat hinge cover rh (w/ rear no.

2 Seat) (see page ir-30)

- Remove no. 2 Seat leg cover lh (w/ rear no. 2 Seat) (see page se-109)

- Remove no. 2 Seat leg cover rh (w/ rear no. 2 Seat) (see page ir-30)

- Remove rear no. 2 Seat assembly lh (w/ rear no. 2 Seat) (see page se-110)

- Remove rear no. 2 Seat assembly rh (w/ rear no. 2 Seat) (see page se-110)

- Remove rear floor no. 2 Board

- Remove rear floor no. 3 Board

- Remove rear no. 1 Floor mat support side plate (see page ir-31)

- Remove back door weatherstrip

- Remove rear floor finish plate (see page ir- 31)

- Remove rear deck trim cover (w/ rear no. 2 Seat)

- Remove reclining remote control lever bezel lh (w/o rear no. 2 Seat)

- Disconnect rear no. 1 Seat outer belt assembly rh

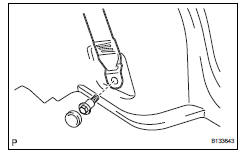

- Remove the lap belt outer anchor cover.

- Remove the bolt and disconnect the floor anchor.

- Disconnect rear no. 2 Seat outer belt assembly lh (w/ rear no. 2 Seat)

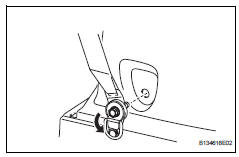

- Open the cover.

- Remove the bolt and disconnect the floor anchor.

- Remove deck trim side panel assembly lh (w/o rear no. 2 Seat) (see page ir-32)

- Remove deck trim side panel assembly lh (w/ rear no. 2 Seat) (see page ir-32)

- Remove inner roof side garnish assembly lh (w/o rear no. 2 Seat) (see page ir-34)

- Remove rear no. 2 Seat outer belt assembly lh (w/ rear no. 2 Seat)

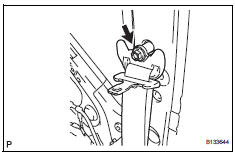

- Using a screwdriver, detach the 2 claws and open the seat belt anchor cover as shown in the illustration.

Hint:

Tape the screwdriver tip before use.

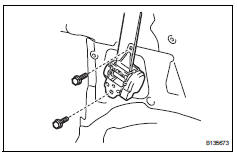

- Remove the bolt and disconnect the seat belt's shoulder anchor.

- Remove the 2 bolts and seat belt.

- Remove inner roof side garnish assembly lh (w/ rear no. 2 Seat) (see page ir-35)

- Remove rear no. 1 Seat outer belt assembly lh

- Remove the bolt and disconnect the seat belt's shoulder anchor.

- Remove the 2 bolts and seat belt.

Inspection

- Inspect rear no. 1 Seat belt assembly outer

Notice:

Do not disassemble the retractor.

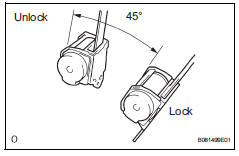

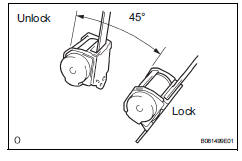

- When the inclination of the retractor is 15Đ or less,

check that the belt can be pulled from the retractor.

When the inclination of the retractor is over 45Ь check that the belt locks.

If the operation is not as specified, replace the belt.

- Inspect rear no. 2 Seat belt assembly outer

Notice:

Do not disassemble the retractor.

- When the inclination of the retractor is 15Đ or less,

check that the belt can be pulled from the retractor.

When the inclination of the retractor is over 45Ь check that the belt locks.

If the operation is not as specified, replace the belt.

Rear seat outer belt assembly

Rear seat outer belt assembly

Components

...

Installation

Installation

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

A bolt without a torque specification is shown in the

standard bolt chart (see pag ...

Other materials:

Using the aux port

This port can be used to connect a portable audio device and listen

to it using the vehicle’s speakers.

Open the cover and connect

the portable audio device.

Press the “media” button repeatedly until “aux” is displayed.

Silencing a sound

Press

(mute).

To cancel, p ...

Front console illumination

On-vehicle inspection

Inspect front console illumination

Connect the battery's positive (+) lead to terminal 1

and the negative (-) lead to terminal 2, then check

that the light comes on.

Ok:

light comes on.

If the result is not as specified, replace the front

console illumin ...

Fuel system

Precaution

Before working on fuel system

Do not work near an open flame.

Keep gasoline away from rubber and leather parts.

Discharge the fuel pressure before disconnecting

the fuel line to prevent gasoline from spilling out.

Refer to the following procedure.

Discharge fuel ...