Toyota RAV4 (XA40) 2013-2018 Service Manual: Mechanical system tests

- Stall speed test

Hint:

This test is to check the overall performance of the engine and transaxle.

Notice:

- Do not perform the stall speed test longer than 5 seconds.

- To ensure safety, perform this test in an open and level area that provides good traction.

- The stall speed test should always be performed with at least 2 people. One person should observe the condition of the wheels and wheel chocks while the other is performing the test.

- Connect the intelligent tester to the can vim. Then connect the can vim to the dlc3.

- Run the vehicle until the transmission fluid temperature has reached 50 to 80°c (122 to 176°f).

- Allow the engine to idle with the air conditioning off.

- Chock all 4 wheels.

- Set the parking brake and keep the brake pedal depressed firmly with your left foot.

- Move the shift lever to the d position.

- Depress the accelerator pedal as much as possible with your right foot.

- Read the engine rpm (stall speed) and release the accelerator pedal immediately.

Standard value: 2,150 to 2,450 rpm

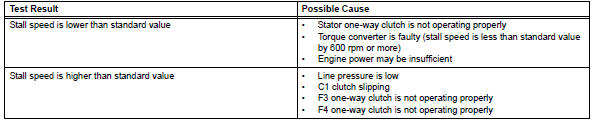

Evaluation:

Notice:

Perform the test at the normal operating atf temperature of 50 to 80°c (122 to 176°f).

- Shift time lag test

Hint:

This test is to check the condition of the direct clutch, forward clutch, 1st brake and reverse brake.

- Connect the intelligent tester to the can vim. Then connect the can vim to the dlc3.

- Run the vehicle until the transmission fluid temperature has reached 50 to 80°c (122 to 176°f).

- Allow the engine to idle with the air conditioning off.

- Set the parking brake and keep the brake pedal depressed firmly.

- Check the d range time lag.

- Move the shift lever to n and wait for 1 minute.

- Move the shift lever to d and measure the time until the shock is felt.

- Repeat the 2 procedures above 3 times, and calculate the average time of the 3 tests.

- Check the r range time lag.

- Move the shift lever to n and wait for 1 minute.

- Move the shift lever to r and measure the time until the shock is felt.

- Repeat the 2 procedures above 3 times, and calculate the average time of the 3 tests.

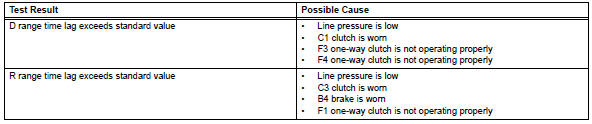

Standard value:

D range time lag is less than 1.2 Seconds

R range time lag is less than 1.5 Seconds

Evaluation:

Road test

Road test

Problem symptom confirmation

Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or ...

Hydraulic test

Hydraulic test

Measure line pressure

Notice:

Perform the test at the normal operating atf

temperature: 50 to 80°c (122 to 176°f).

The line pressure test should always be

performed with at least ...

Other materials:

Cleaning and protecting the vehicle interior

Perform cleaning in a manner

appropriate to each

component and its material.

Protecting the vehicle

interior

Remove dirt and dust using a

vacuum cleaner. Wipe dirty

surfaces with a cloth dampened

with lukewarm water.

If dirt cannot be removed,

wipe it off with a soft cloth

dampened with neut ...

Seat heaters

Turns on the front left seat

heater (high)

Turns on the front left seat

heater (low)

Turns on the front right seat

heater (high)

Turns on the front right seat

heater (low)

The indicator light comes on.

The seat heaters can be used when

Vehicles without a smart key system

T ...

Only back door lock / unlock functions do not operate

Description

The main body ecu receives lock / unlock switch signals and activates the

door lock motor accordingly.

Wiring diagram

Inspection procedure

Inspect back door with motor lock assembly

Apply the battery voltage to the door lock motor and

check the operation of the d ...