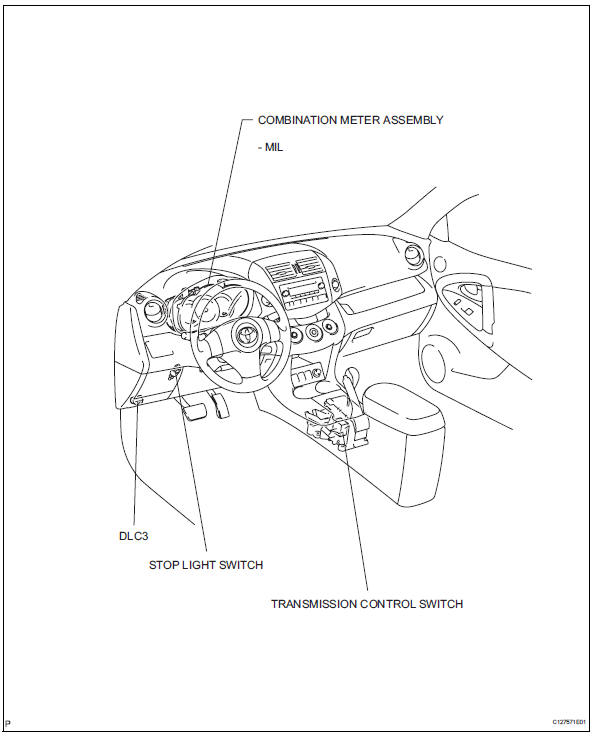

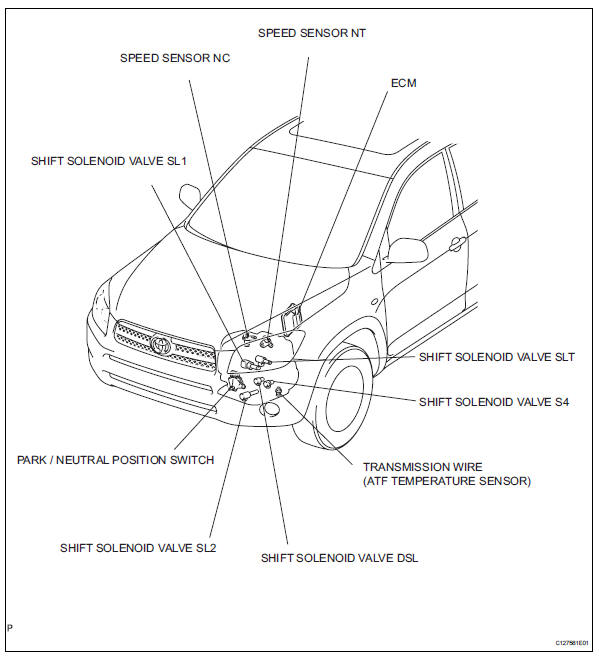

Toyota RAV4 (XA40) 2013-2018 Service Manual: Parts location

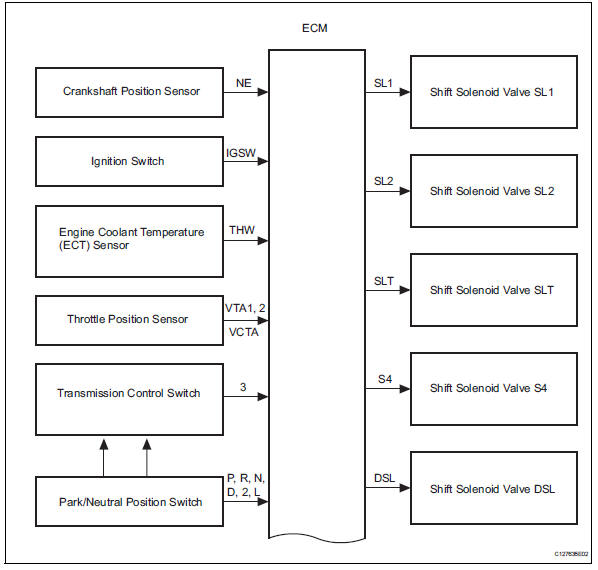

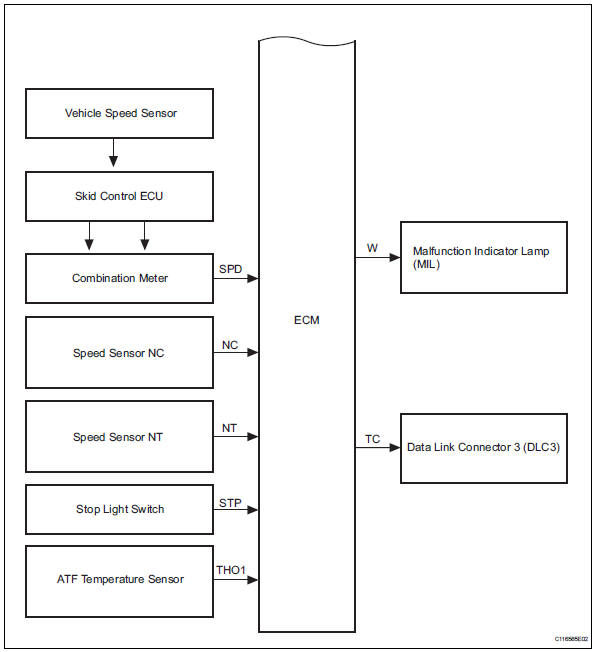

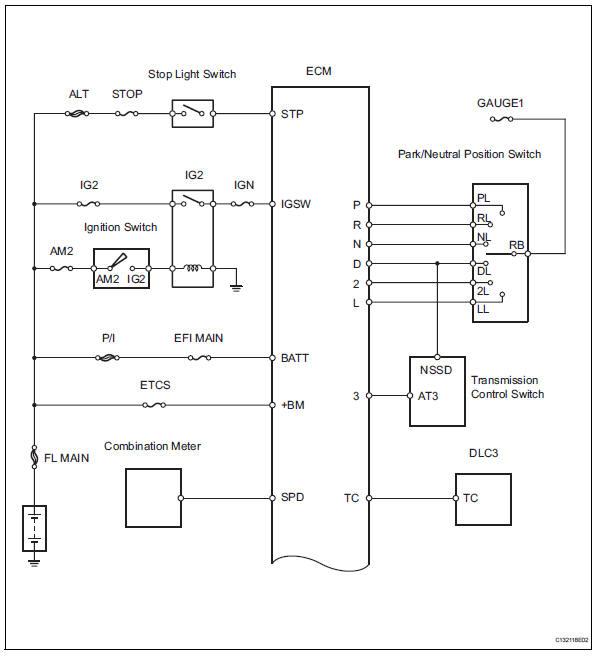

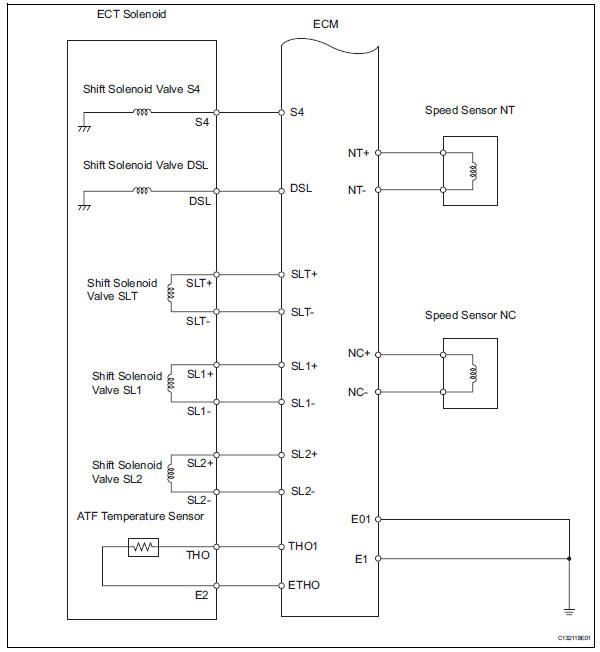

System diagram

The configuration of the electronic control system in the u140f automatic transaxle is as shown in the following chart.

System description

- System description

- The electronic controlled automatic transaxle

(ect) is an automatic transaxle that electronically

controls shift timing using the engine control

module (ecm). The ecm detects electrical signals

that indicate engine and driving conditions, and

controls the shift point based on driver habits and

road conditions. As a result, fuel efficiency and

power transaxle performance are improved.

Shift shock is reduced by controlling the engine and transaxle simultaneously.

In addition, the ect has the following features:

- Diagnostic function.

- Fail-safe function when a malfunction occurs.

How to proceed with troubleshooting

Hint:

- The ecm of this system is connected to the can and multiplex communication system. Therefore, before starting troubleshooting, make sure to check that there is no trouble in the can and multiplex communication systems.

- *: Use the intelligent tester.

- Vehicle brought to workshop

- Customer problem analysis

- Inspect battery voltage

Standard voltage: 11 to 14 v

If the voltage is below 11 v, recharge or replace the battery before proceeding.

- Connect intelligent tester to dlc3*

- Check and clear dtcs and freeze frame data*

- Refer to the dtc check / clear (see page ax-29).

- Visual inspection

- Setting check mode diagnosis*

- Refer to the check mode procedure (see page ax-30).

- Problem symptom confirmation

- Refer to the road test (see page ax-12).

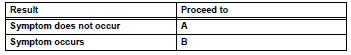

Result

- Symptom simulation

- Refer to the electronic circuit inspection procedure (see page in-37).

- Dtc check*

- Refer to the dtc check / clear (see page ax-29).

Result

- Basic inspection

- Refer to the automatic transmission fluid (see page ax-102).

- Refer to the park/neutral position switch (see page ax-108).

- Refer to the floor shift assembly (see page ax- 136).

- Mechanical system tests

- Refer to the mechanical system tests (see page ax-15).

- Hydraulic test

- Refer to the hydraulic test (see page ax-16).

- Manual shifting test

- Refer to the manual shifting test (see page ax- 17).

- Problem symptoms table chapter 1

- Refer to the problem symptoms table (see page ax-21).

- Problem symptoms table chapter 2

- Refer to the problem symptoms table (see page ax-21).

- Part inspection

- Dtc chart

- Refer to the diagnostic trouble code chart (see page ax-35).

- Circuit inspection

- Identification of problem

- Repair or replace

- Confirmation test

End

Precaution

Precaution

Notice:

Perform the reset memory procedures (a/t

initialization) when replacing the automatic transaxle

assembly, engine assembly or ecm (see page ax-18).

Hint:

Reset memory cannot be completed b ...

Road test

Road test

Problem symptom confirmation

Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or ...

Other materials:

Rear seats

Adjustment procedure

Pull up the lever. Then lean back to the desired angle and release the

lever.

When a person sits in the rear center position, align all seatbacks at the

same angle.

Folding down the rear seatbacks

Before folding down the rear seatbacks

Stow the rear center seat bel ...

Installation

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

When installing the moulding, heat the vehicle body and

moulding using a heat light.

Standard heating temperature

Notice:

Do not heat the vehicle body and moulding

excessively ...

Fail-safe chart

If a problem occurs in the electric power steering system, the

p/s warning light will come on in the combination meter and

steering power assist will be stopped, fixed at a particular

point, or decreased simultaneously to protect the system.

Hint:

The amount of power assist may be decreased ...