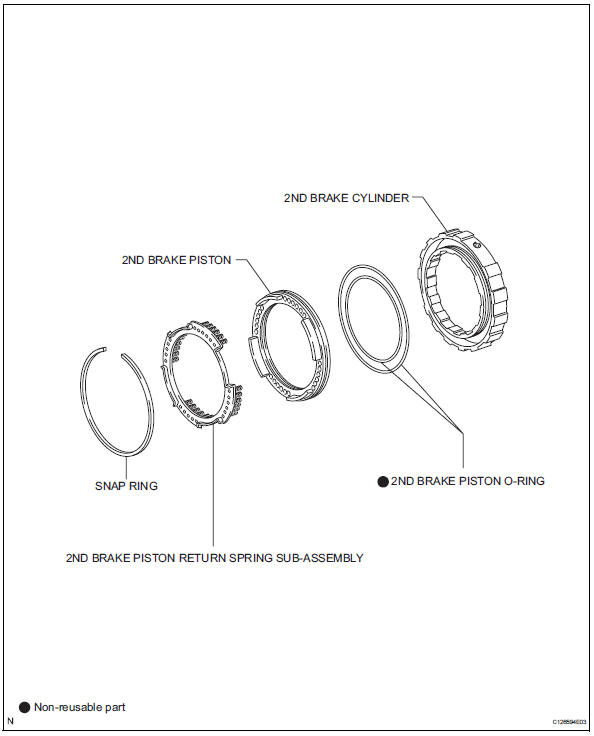

Toyota RAV4 (XA40) 2013-2018 Service Manual: Second brake piston

Components

Disassembly

- Remove 2nd brake piston return spring sub-assembly

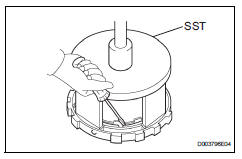

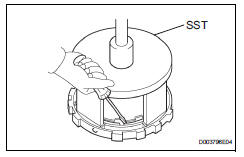

- Place sst on the return spring and compress.

- Using a screwdriver, pry out the snap ring.

- Remove the piston return spring.

- Inspect 2nd brake piston return spring sub-assembly (see page ax-223)

- Remove 2nd brake piston

- Hold the 2nd brake piston and apply compressed air (392 kpa, 4.0Kgf/cm2, 57 psi) to the 2nd brake cylinder to remove the 2nd brake piston.

- Remove 2nd brake piston o-ring

- Remove the 2 o-rings from the 2nd brake piston.

Inspection

- Inspect 2nd brake piston return spring sub-assembly

- Using a vernier caliper, measure the free length of the spring together with the spring seat.

Standard free length: 16.61 Mm (0.6539 In.)

Reassembly

- Install 2nd brake piston o-ring

- Coat the 2 new o-rings with atf, and install them into the 2nd brake piston.

- Install 2nd brake piston

- Press in the 2nd brake piston into the 2nd brake cylinder with your hands.

- Install 2nd brake piston return spring sub-assembly

- Install the piston return spring.

- Place sst on the piston return spring, and compress the piston return spring with a press.

Sst 09387-00060

- Using a screwdriver, install the snap ring.

Notice:

Be sure the end gap of the snap ring is not aligned with the piston return spring claw.

Reassembly

Reassembly

Install front oil pump oil seal

Using sst and a hammer, install a new oil seal to

the pump.

Sst 09350-32014 (09351-32140)

Hint:

The seal end should be flat with the outer edge of

...

Forward clutch

Forward clutch

Components

Disassembly

Inspect forward clutch (see page ax-227)

Remove forward multiple disc clutch disc

Using a screwdriver, remove the snap ring.

Remove the flange , 5 discs a ...

Other materials:

Outer rear view mirror

Components

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Remove front door lower frame bracket

garnish lh (see page ed-19)

Remove front armrest upper base panel

lh (see page ed-19)

Remove front door t ...

Disposal

Hint:

When scrapping a vehicle equipped with an srs or disposing

of the curtain shield airbag assembly, be sure to deploy the

airbag first in accordance with the procedure described

below. If any abnormality occurs with the airbag deployment,

contact the service dept. Of toyota motor sales,

u. ...

Gauges and meters

The units used on the speedometer may differ depending on the target

region.

Tachometer

Displays the engine speed in revolutions per minute

Speedometer

Displays the vehicle speed

Fuel gauge

Displays the quantity of fuel remaining in the tank

Shift position and shift ran ...