Toyota RAV4 (XA40) 2013-2018 Service Manual: Torque converter clutch solenoid circuit

Description

The shift solenoid valve dsl is turned on and off by signals from the ecm to control the hydraulic pressure acting on the lock-up relay valve, which then controls operation of the lock-up clutch.

Fail-safe function: if the ecm detects a malfunction, it turns the shift solenoid valve dsl off.

Monitor description

Torque converter lock-up is controlled by the ecm based on engine rpm, engine load, engine temperature, vehicle speed, transmission temperature, and shift position selection. The ecm determines the lock-up status of the torque converter by comparing the engine rpm (ne) to the input rpm (nt). The ecm calculates the actual transmission gear by comparing the input rpm (nt) to the output rpm (sp2).

When conditions are appropriate, the ecm requests "lock-up" by applying control voltage to the shift solenoid valve dsl. When the shift solenoid valve dsl is opened, the shift solenoid valve dsl applies pressure to the lock-up relay valve and locks the torque converter clutch. If the ecm detects an open or short in the shift solenoid valve dsl circuit, the ecm interprets this as a fault in the shift solenoid valve dsl or its circuit. The ecm will illuminate the mil and store a dtc.

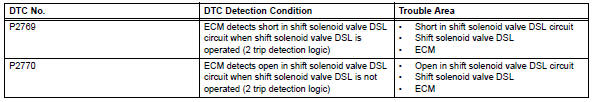

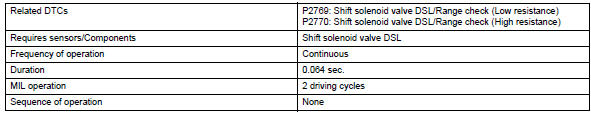

Monitor strategy

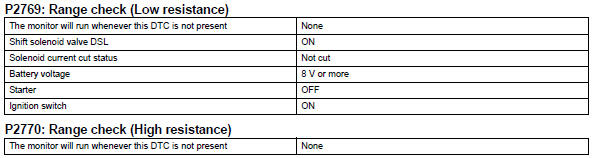

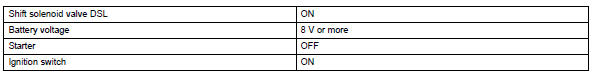

Typical enabling conditions

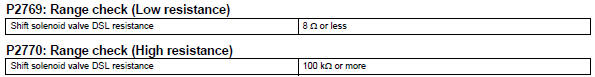

Typical malfunction thresholds

Component operating range

![]()

Wiring diagram

Refer to dtc p0741 (see page ax-62).

Inspection procedure

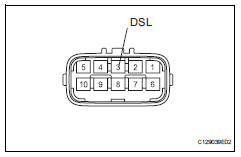

- Inspect transmission wire (shift solenoid valve dsl)

- Disconnect the b27 wire connector.

- Measure the resistance of the transmission wire.

Standard resistance

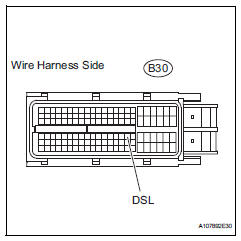

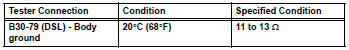

- Check wire harness (transmission wire - ecm)

- Disconnect the b30 ecm connector.

- Measure the resistance of the wire harness side connector.

Standard resistance

Replace ecm

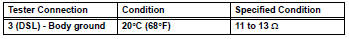

- Inspect shift solenoid valve dsl

- Remove the shift solenoid valve dsl.

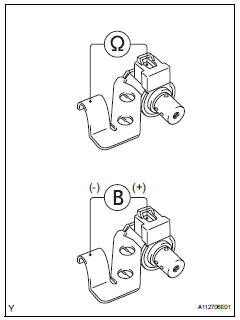

- Measure the resistance between the solenoid valve terminal and solenoid valve body.

Standard resistance:

11 to 13  at 20°c (68°f)

at 20°c (68°f)

- Connect the battery's positive (+) lead to the terminal of the solenoid valve connector, and the negative (-) lead to the solenoid body. Then check that the valve moves and makes an operating noise.

Ok: valve moves and makes operating noise.

Repair or replace transmission wire

Pressure control solenoid "d" electrical (shift solenoid valve slt)

Pressure control solenoid "d" electrical (shift solenoid valve slt)

Description

Refer to dtc p2714 (see page ax-91).

Monitor description

When an open or short in the shift solenoid valve slt circuit is detected,

the ecm interprets this as a fault.

The ...

Automatic transaxle fluid

Automatic transaxle fluid

On-vehicle inspection

Check transaxle fluid level

Hint:

Drive the vehicle so that the engine and transaxle are at

normal operating temperature.

Fluid temperature:

70 to 80°c (158 to 176°f ...

Other materials:

Disassembly

Remove radiator grille sub-assembly

Remove the 4 bolts and 4 nuts.

Detach the 6 claws and remove the radiator grille.

Remove no. 1 Radiator grille lower

Detach the 18 claws and remove the radiator grille.

Remove no. 2 Radiator grille lower

Detac ...

Console box

Lift the lid while pulling up the

lever to release the lock.

When using the console box lid as an armrest (vehicles with slide

function)

Slide the console box lid forward as

needed. Pull the lid forward by holding the

front of the lid.

Caution

Console box adjustment precaution

D ...

Unlock warning switch

Inspection

Inspect unlock warning switch assembly

Measure the resistance of the switch.

Standard resistance

If the result is not as specified, replace the switch

assembly.

Ecu power source circuit

Description

This circuit provides power to operate the transponder key ecu.

Wir ...