Toyota RAV4 (XA40) 2013-2018 Service Manual: Underdrive planetary gear

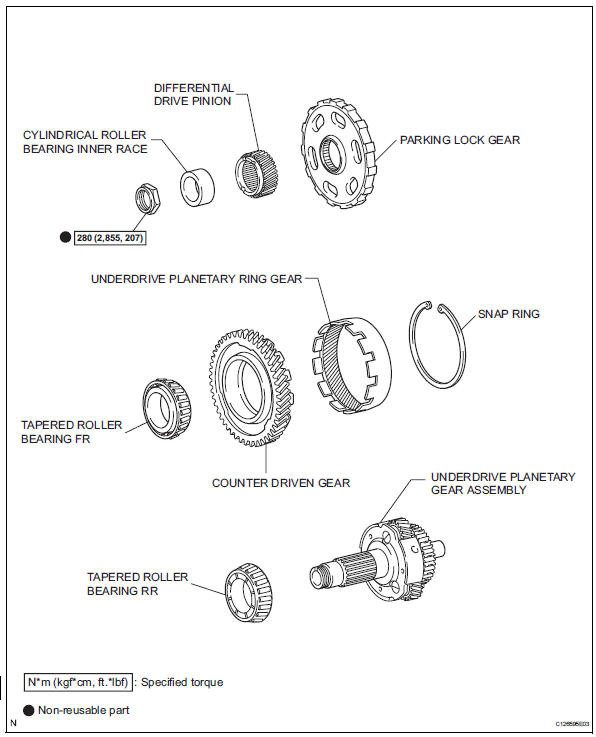

Components

Disassembly

- Remove underdrive planetary gear preload (see page ax-240)

- Remove underdrive input shaft nut

Sst 09930-00010 (09931-00010, 09931-00020), 09387-00050, 09564-16020

- Using sst, loosen the staked part of the nut.

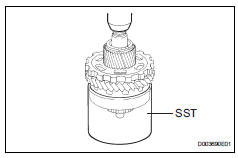

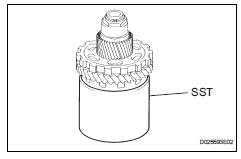

- Clamp the underdrive planetary gear in soft jaw vise.

Notice:

Be careful not to damage the differential drive pinion.

- Using sst, remove the lock nut.

Sst 09387-00050

- Remove cylindrical roller bearing inner race

- Using sst, remove the cylindrical roller bearing race inner.

Sst 09950-00020, 09950-00030, 09950-60010 (09951-00340)

- Remove underdrive planetary gear assembly

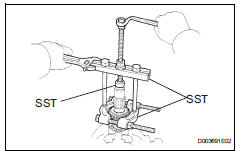

- Using sst and a press, remove the differential drive pinion, parking lock gear, counter driven gear with underdrive planetary ring gear and front tapered roller bearing.

Sst 09387-00050

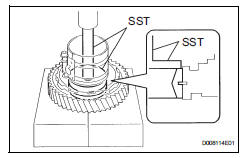

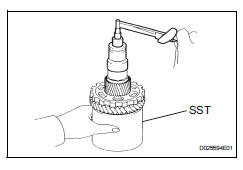

- clamp the underdrive planetary gear in soft jaw vise.

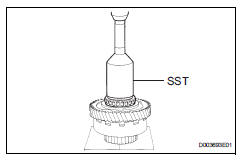

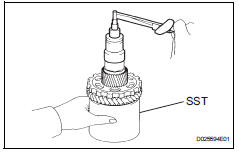

- Using sst, remove the rear tapped roller bearing from the underdrive planetary gear.

Sst 09950-00020, 09950-00030, 09950-60010 (09951-00340)

- Remove underdrive planetary ring gear

- Using snap ring pliers, remove the snap ring.

- Remove the underdrive planetary ring gear from the counter driven gear.

Inspection

- Inspect underdrive planetary gear preload

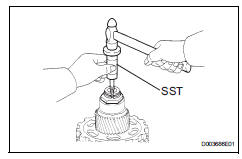

- Using sst, fix the underdrive planetary gear.

Sst 09387-00050

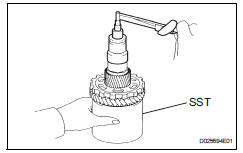

- Using sst and a torque wrench, measure the turning torque of the underdrive planetary gear in place while rotating the torque wrench at 60 rpm.

Sst 09387-00050

Torque: turning torque at 60 rpm

0.10 To 4.41 N*m (1.0 To 45 kgf*cm, 0.9 To 39 in.*Lbf)

Hint:

Use a torque wrench with a fulcrum length of 160 mm (6.3 In.)

Reassembly

- Install underdrive planetary ring gear

- Install a new snap ring to the outer race of the tapered roller bearing.

- Using a piston ring compressor, squeeze the snap ring.

- Using sst a press, press in the outer race of the tapered roller bearing.

Sst 09950-60020 (09951-00890), 09950-70010 (09951-07100)

- Install the underdrive planetary ring gear to the counter driven gear.

- Using snap ring pliers, install the snap ring.

- Install underdrive planetary gear assembly

- Using a press, press in the rear tapered roller bearing to the underdrive planetary gear.

Notice:

Press in the bearing until it becomes flat at the bottom

- Press in the bearing until it becomes flat at the bottom

- Using sst and a press, press in the front tapered roller bearing.

Sst 09214-76011

Notice:

Press in the counter driven gear while rotating it.

- Using a press, press in the parking lock gear.

Notice:

Press in the counter driven gear while rotating it.

- Install cylindrical roller bearing inner race

- Using a press, press in the cylindrical roller bearing race inner.

Notice:

Press in the counter driven gear while rotating it.

- Install underdrive input shaft nut

- Clamp the underdrive planetary gear in a soft jaw vise.

Notice:

Be careful not to damage the differential drive pinion.

- Using a socket wrench, install a new lock nut.

Torque: 280 n*m (2,855 kgf*cm, 207 in.*Lbf)

Hint:

Use a torque wrench with a fulcrum length of 750 mm (29.53 In.)

- Inspect underdrive planetary gear preload

- Using sst and a torque wrench, measure the turning torque of underdrive planetary gear assembly while rotating the torque wrench at 60 rpm.

Sst 09387-00050

Torque: turning torque at 60 rpm 0.10 To 4.41 N*m (1.0 To 45 kgf*cm, 0.9 To 39 in.*Lbf)

Hint:

Use a torque wrench with a fulcrum length of 160 mm (6.30 In.)

- Using a pin punch and a hammer, stake the lock nut.

Notice:

Make sure that there are no cracks on the nut.

Direct clutch

Direct clutch

Components

Disassembly

Inspect pack clearance of direct clutch

(see page ax-234)

Remove direct multiple disc clutch disc

Using a screwdriver, pry out the snap ring from the

direct ...

Underdrive clutch

Underdrive clutch

Components

Disassembly

Inspect pack clearance of underdrive

clutch (see page ax-247)

Remove no. 1 Underdrive clutch disc

Using a screwdriver, pry out the underdrive clutch

fla ...

Other materials:

SRS airbags

The SRS airbags inflate when the vehicle is subjected to certain

types of severe impacts that may cause significant injury

to the occupants. They work together with the seat belts to

help reduce the risk of death or serious injury.

SRS airbag system

â– Location of the SRS airbags

SRS front airbags ...

Adding engine oil

â– Checking the oil type and

preparing the items needed

Make sure to check the oil type

and prepare the items needed

before adding oil.

Engine oil selection

Oil quantity (Low level mark

Refill upper limit mark)

1.6 qt. (1.5 L, 1.3 Imp. qt.)

Item

Clean funnel

â– Adding engine oil

If the oi ...

Blower resistor

On-vehicle inspection

Inspect blower motor control

Measure the resistance of the blower resistor.

Standard resistance

If the resistance is not as specified, replace the

blower motor control. ...