Toyota RAV4 (XA50) 2019-2026 Owners Manual: Air conditioning filter

The air conditioning filter must be changed regularly to maintain air conditioning efficiency.

Removal method

1. Turn the engine switch to OFF.

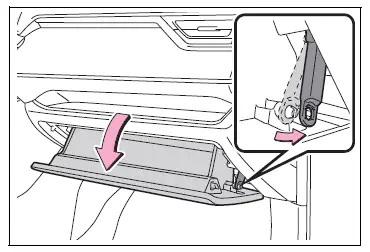

2. Open the glove box and slide off the damper.

3. Push in each side of the glove box to disconnect the claws, and then slowly and fully open the glove box while supporting it.

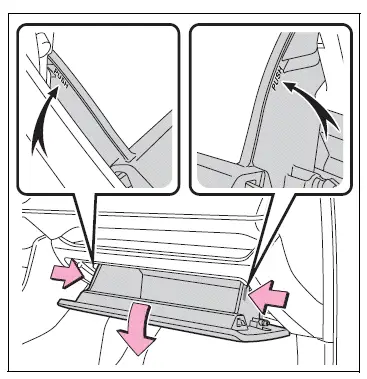

4. With the glove box fully open, slightly lift up the glove box and pull toward the seat to detach the bottom of the glove box.

Do not use excessive force if the glove box does not detach when lightly pulled. Instead, pull toward the seat while slightly adjusting the height of the glove box.

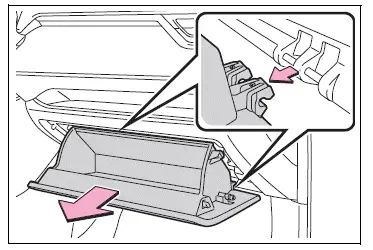

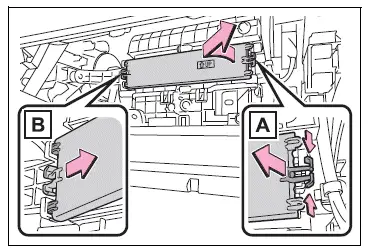

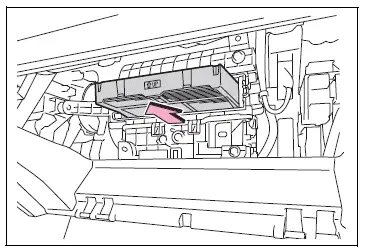

5. Unlock the filter cover (A), pull the filter cover out of the claws (B), and remove the filter cover.

6. Remove the filter case.

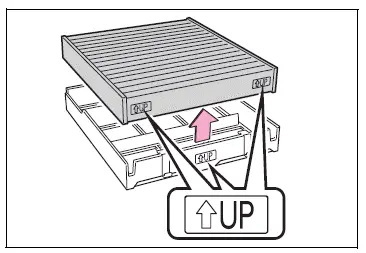

7. Remove the air conditioning filter from the filter case and replace it with a new one.

The " UP" marks shown on the

UP" marks shown on the

filter should be pointing up.

8. When installing, reverse the steps listed.

â– Checking interval

Inspect and replace the air conditioning filter according to the maintenance schedule. In dusty areas or areas with heavy traffic flow, early replacement may be required. (For scheduled maintenance information, please refer to the "Owner's Manual Supplement" or "Scheduled Maintenance".)

â– If air flow from the vents decreases dramatically

The filter may be clogged. Check the filter and replace if necessary.

NOTICE

â– When using the air conditioning system

Make sure that a filter is always installed.

Using the air conditioning system without a filter may cause damage to the system.

â– When removing the glove box

Always follow the specified procedure to remove the glove box. If the glove box is removed without following the specified procedure, the hinge of the glove box may become damaged.

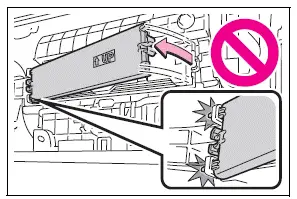

â– To prevent damage to the filter cover

When moving the filter cover in the direction of arrow to release the fitting, pay attention not to apply excessive force to the claws. Otherwise, the claws may be damaged.

Wheels

Wheels

If a wheel is bent, cracked or

heavily corroded, it should

be replaced. Otherwise, the

tire may separate from the

wheel or cause a loss of

handling control.

Wheel selection

When replacing wheels, care ...

Wiper insert replacement

Wiper insert replacement

When replacing the wiper

insert, perform the following

procedure to operate each

wiper.

Windshield wipers

â– Windshield wiper blade

removal and installation

1. While holding the hook portion A

of the ...

Other materials:

Parking brake system

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order th ...

Parts location

System diagram

...

Check for intermittent problems

Hint:

Inspect the vehicle's ecm using check mode. Intermittent

problems are easier to detect with the intelligent tester when

the ecm is in check mode. In check mode, the ecm uses 1

trip detection logic, which is more sensitive to malfunctions

than normal mode (default), which uses 2 trip detec ...