Toyota RAV4 (XA40) 2013-2018 Service Manual: Camshaft position correlation (bank 1 sensor a)

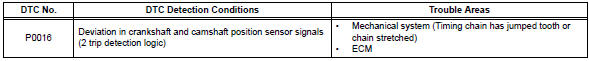

Dtc

P0016 P0016 crankshaft position - camshaft position correlation (bank 1 sensor a)

Description

In the vvt (variable valve timing) system, the appropriate intake valve open and close timing is controlled by the ecm. The ecm performs intake valve control by performing the following: 1) controlling the camshaft and camshaft timing oil control valve, and operating the camshaft timing gear; and 2) changing the relative positions of the gaps between the camshaft and crankshaft

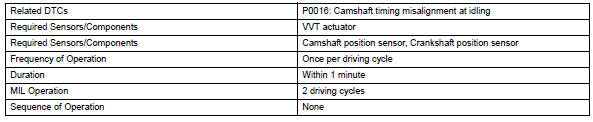

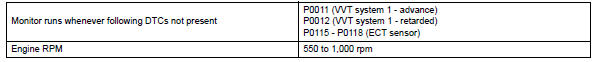

Monitor description

The ecm optimizes the valve timing by using the vvt (variable valve timing) system to control the intake camshaft. The vvt system includes the ecm, the oil control valve (ocv) and the vvt controller.

The ecm sends a target duty-cycle control signal to the ocv. This control signal regulates the oil pressure supplied to the vvt controller. The vvt controller can advance or retard the intake camshaft.

The ecm calibrates the intake valve timing by setting the intake camshaft to the most retarded angle while the engine is idling. The ecm closes the ocv to retard the cam. The ecm stores this value as the vvt learning value. When the difference between the target and actual intake valve timings is 5°ca (crankshaft angle) or less, the ecm stores it.

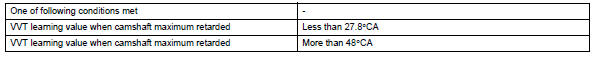

If the vvt learning value matches the following conditions, the ecm determines the existence of a malfunction in the vvt system, and sets the dtc.

- Vvt learning value: less than 25°ca, or more than 51°ca.

- Above condition continues for 18 seconds or more.

This dtc indicates that the angle between the intake camshaft and the crankshaft is incorrect due to factors such as the timing chain having jumped a tooth.

This monitor begins to run after the engine has idled for 5 minutes.

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0335 (see page es-172).

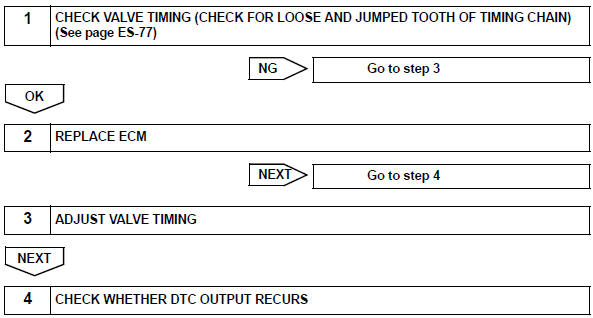

Inspection procedure

Hint:

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

Notice:

After replacing the ecm or adjusting intake valve timing, confirm that the dtc output does not recur.

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Clear dtcs (see page es-35).

- Switch the ecm from normal mode to check mode using the tester (see page es-38).

- Start the engine and warm it up.

- Allow the engine to idle for 1 minute or more, and then drive the vehicle for 1 minute or more.

- Confirm that no dtc is set, using the tester.

Ok: no dtc output

Camshaft position "A"

Camshaft position "A"

Dtc P0011 Camshaft position

"a" - timing over-advanced or system performance (bank 1)

Dtc P0012 Camshaft

position "a" - timing over-retarded (bank 1)

Description

The v ...

Oxygen (a/f) sensor heater control circuit

Oxygen (a/f) sensor heater control circuit

Hint:

Although the dtc titles say oxygen sensor, these dtcs relate to the

air-fuel ratio (a/f) sensor.

Sensor 1 refers to the sensor mounted in front of the three-way

catalytic convert ...

Other materials:

Check for intermittent problems

Hint:

Inspect the vehicle's ecm using check mode. Intermittent

problems are easier to detect with the intelligent tester when

the ecm is in check mode. In check mode, the ecm uses 1

trip detection logic, which is more sensitive to malfunctions

than normal mode (default), which uses 2 trip detec ...

Fail-safe chart

Fail-safe function

When communication fails in any of the main wires

(communication lines) due to a short circuit or other

causes, the fail-safe function, which is specified for

each system, operates to prevent the system from

malfunctioning.

The table below shows the effects on e ...

Battery current sensor circuit

Description

The battery current sensor installed on the positive (+) battery terminal

detects the amount of current

supplied from the generator.

The battery current sensor changes current to voltage (at the positive (+)

battery terminal) and sends it to

the ecm. The ecm controls th ...