Toyota RAV4 (XA40) 2013-2018 Service Manual: Crankshaft position sensor "A"

Description

The crankshaft position (ckp) sensor system consists of a ckp sensor plate and a pickup coil.

The sensor plate has 34 teeth and is installed on the crankshaft. The pickup coil is made of wound copper wire, an iron core and magnet. The sensor plate rotates and, as each tooth passes through the pickup coil, a pulse signal is created. The pickup coil generates 34 signals per engine revolution. Based on these signals, the ecm calculates the crankshaft position and engine rpm. Using these calculations, the fuel injection time and ignition timing are controlled.

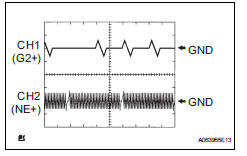

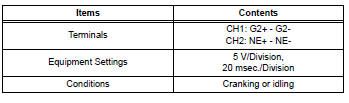

Reference: inspection using an oscilloscope.

Hint:

- The correct waveform is as shown.

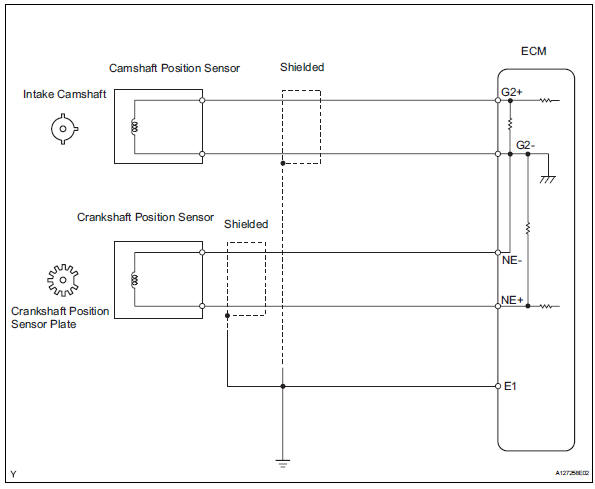

- G2+ stands for the camshaft position (cmp) sensor signal, and ne+ stands for the ckp sensor signal.

- Grounding failure of the shielded wire may cause noise in waveforms.

Monitor description

If there is no signal from the ckp sensor despite the engine revolving, the ecm interprets this as a malfunction of the sensor.

If the malfunction is not repaired successfully, a dtc is set 10 seconds after the engine is next started.

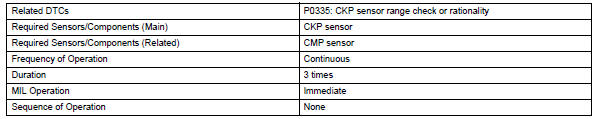

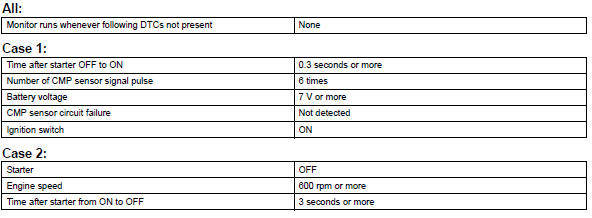

Monitor strategy

Typical enabling conditions

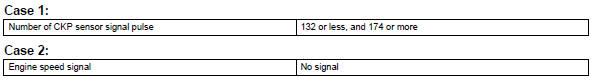

Typical malfunction thresholds

Component operating range

![]()

Wiring diagram

Inspection procedure

Hint:

- If no problem is found through this diagnostic troubleshoot procedure, troubleshoot the engine mechanical systems.

- Check the engine speed. The engine speed can be checked by using the intelligent tester. To check, follow the operation below:

- Connect the intelligent tester to the dlc3.

- Start the engine.

- Turn the tester on

- Select the following menu items: diagnosis / enhanced obd ii / data list / primary / engine spd.

The engine speed may be indicated as zero despite the engine revolving normally. This is caused by a lack of ne signals from the crankshaft position (ckp) sensor. Alternatively, the engine speed may be indicated as lower than the actual engine speed if the ckp sensor output voltage is insufficient.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

- Read value using intelligent tester (engine spd)

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / data list / primary / engine spd.

- Start the engine.

- Read the values displayed on the tester while the engine is running.

Standard: correct values are displayed.

Hint:

- To check the engine speed change, display the graph on the tester.

- If the engine does not start, check the engine speed while cranking.

- If the engine speed indicated on the tester remains zero (0), there may be an open or short in the crankshaft position (ckp) sensor circuit.

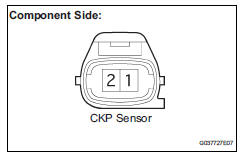

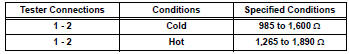

- Inspect crankshaft position sensor (resistance)

- Disconnect the b22 ckp sensor connector.

- Measure the resistance between terminals 1 and 2.

Standard resistance

Hint:

Terms cold and hot refer to the temperature of the sensor. Cold means approximately -10 to 50°c (14 to 122°f). Hot means approximately 50 to 100°c (122 to 212°f).

- Reconnect the ckp sensor connector.

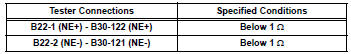

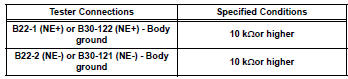

- Check harness and connector (crankshaft position sensor - ecm)

- Disconnect the b22 ckp sensor connector.

- Disconnect the b30 ecm connector.

- Measure the resistance.

Standard resistance (check for open)

Standard resistance (check for short)

- Reconnect the ecm connector.

- Reconnect the ckp sensor connector.

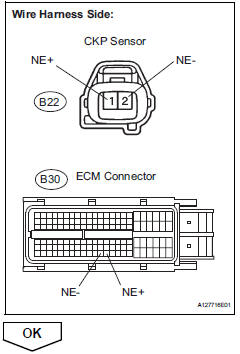

- Check sensor installation (crankshaft position sensor)

- Check the ckp sensor installation.

Ok: sensor is installed correctly.

- Check crankshaft position sensor plate (teeth of sensor plate)

- Check the teeth of the sensor plate.

Ok: sensor plate does not have any cracks or deformation.

- Replace crankshaft position sensor

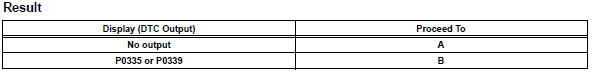

- Check whether dtc output recurs

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Clear dtcs (see page es-35).

- Start the engine.

- Select the following menu items: diagnosis / enhanced obd ii / dtc info / current codes.

- Read dtcs.

Hint:

If the engine does not start, replace the ecm.

Knock sensor 1 circuit

Knock sensor 1 circuit

Description

Flat type knock sensors (non-resonant type) have structures that can detect

vibrations over a wide band

of frequencies: between approximately 6 khz and 15 khz.

A knock sensor is ...

Camshaft position sensor "a" circuit (bank 1 or single sensor)

Camshaft position sensor "a" circuit (bank 1 or single sensor)

Description

The camshaft position (cmp) sensor consists of a magnet and an iron core

which is wrapped with copper

wire, and is installed onto the cylinder head. When the camshaft rotates, each ...

Other materials:

Components

...

Front brake

Components

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Remove front wheel

Drain brake fluid

Notice:

Wash off brake fluid immediately if it comes in

contact with any painted surface.

Disconnec ...

Ig power source circuit

Description

This is the main power source supplied to the air conditioning amplifier when

the ignition switch is on.

This power source is used for operating components, such as the air conditioning

amplifier and servo

motors.

Wiring diagram

Inspection procedure

Inspect fuse (ecu-i ...