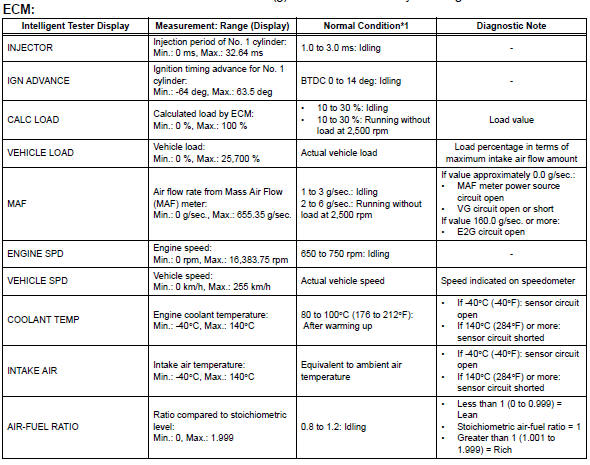

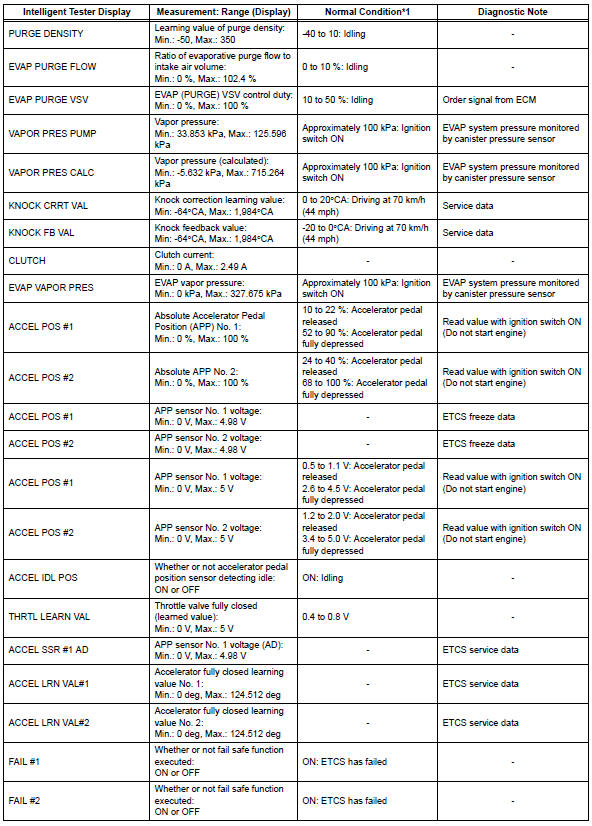

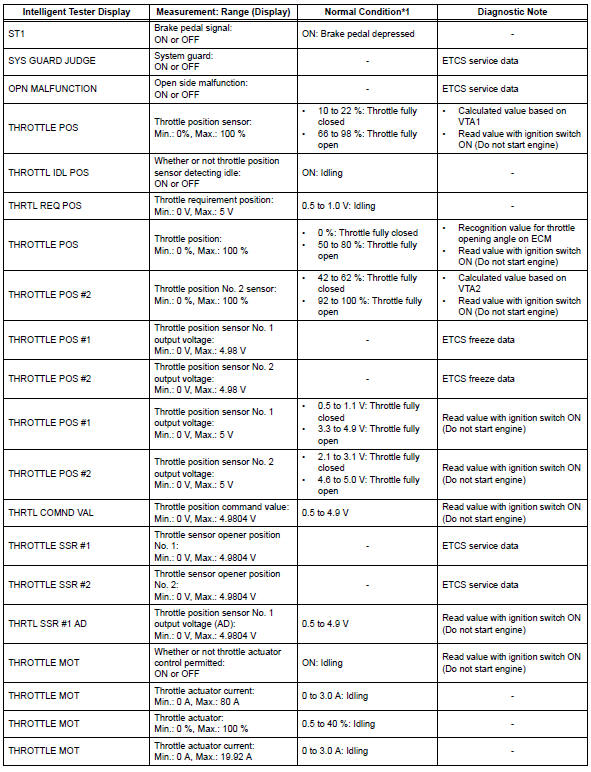

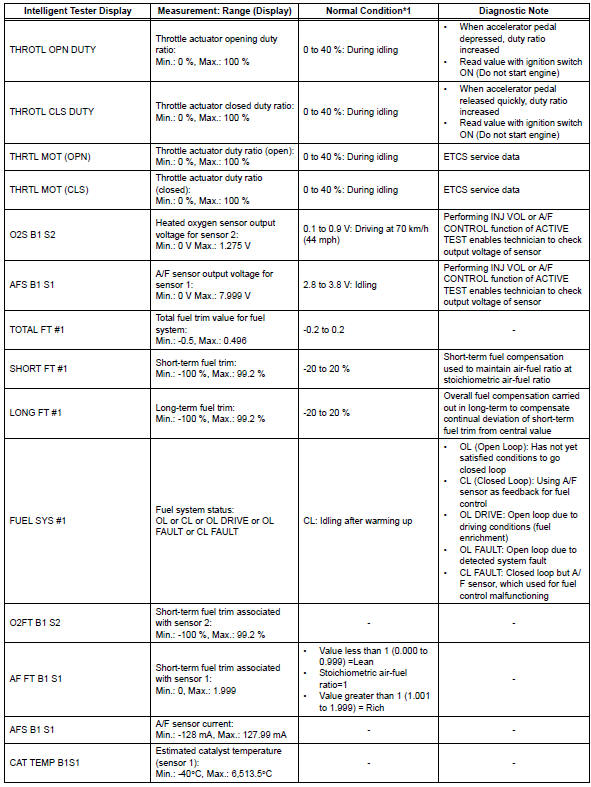

Toyota RAV4 (XA40) 2013-2018 Service Manual: Data list

Hint:

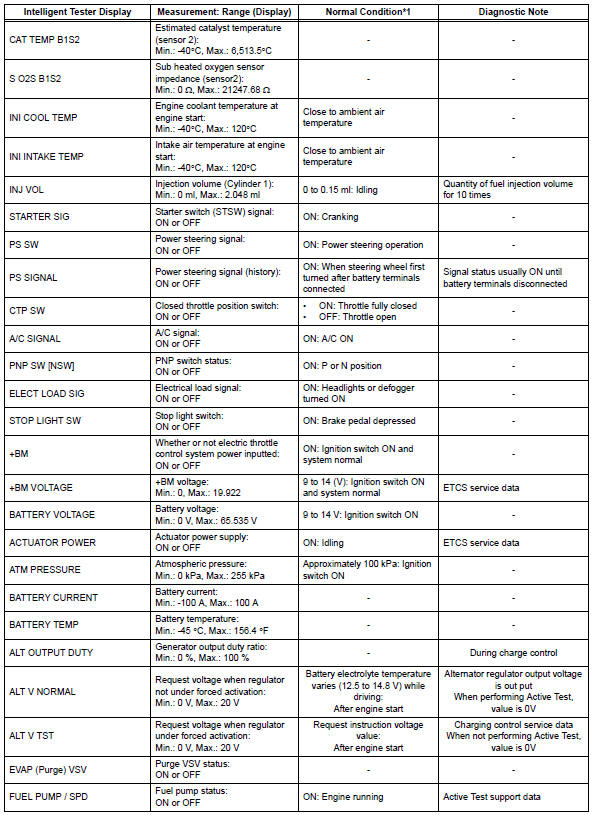

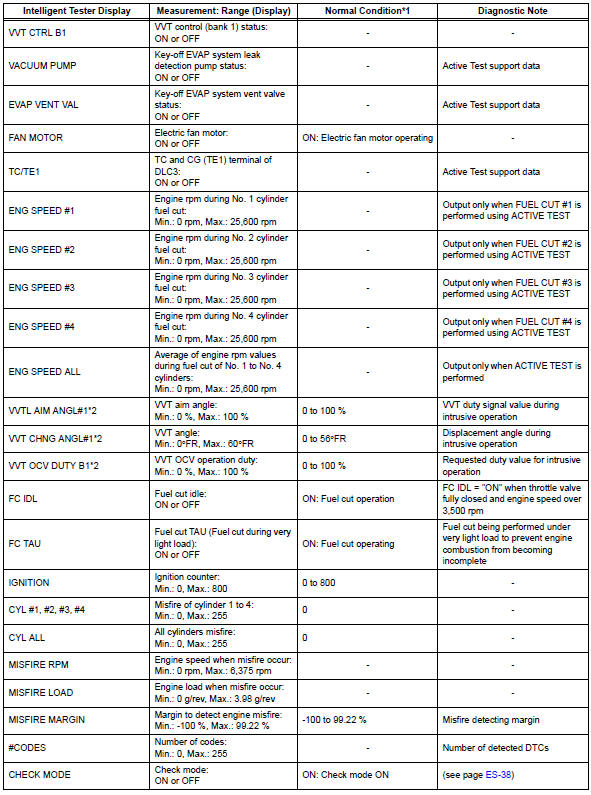

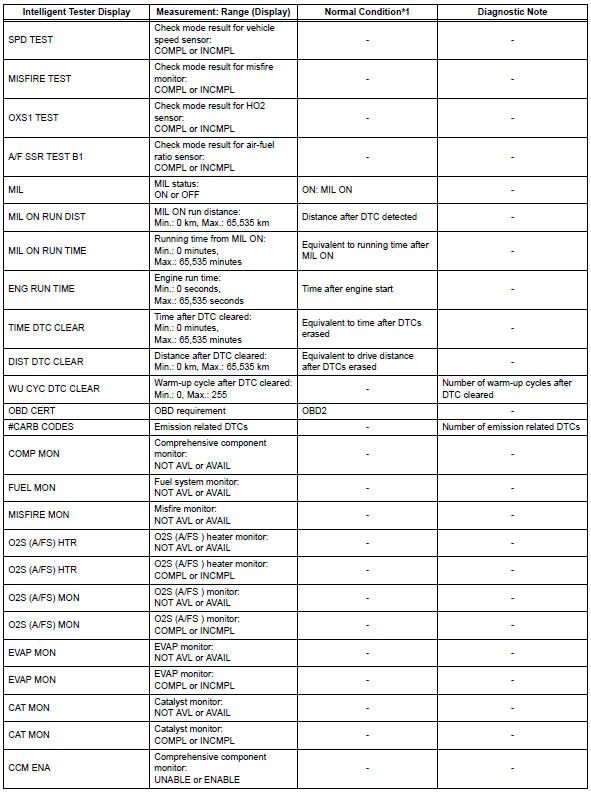

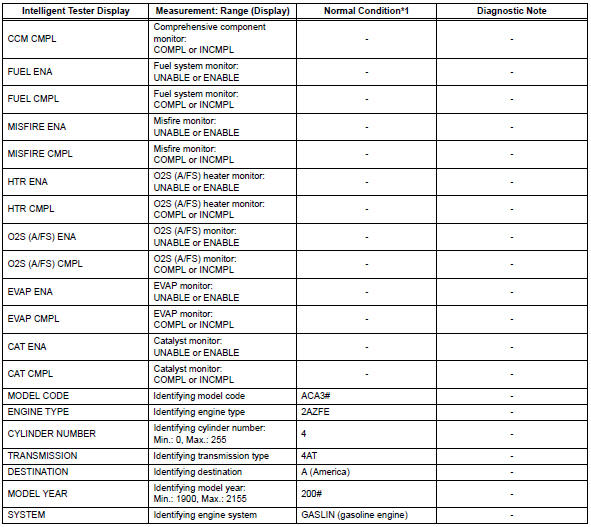

By reading the data list displayed on an intelligent tester, values can be checked, including those of the switches, sensors, and actuators, without removing any parts. Reading the data list as the first step of troubleshooting is one method of shortening diagnostic time.

Notice:

In the table below, the values listed under normal condition are for reference only. Do not depend solely on these values when determining whether or not a part is faulty.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / data list

- Check the values by referring to the table below.

Hint:

- *1: If no idling conditions are specified, the transmission gear selector lever should be in the n or p position, and the a/c switch and all accessory switches should be off.

- *2: Data list values are only displayed when performing the following active test: vvt b1. For other active tests, the data list value will be 0.

Active test

Active test

Hint:

Performing an active test enables components

including the relays, vsv (vacuum switching valve) and

actuators, to be operated without removing any parts.

The active test can be performed w ...

Other materials:

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove front seat assembly lh

Remove the front seat.

For manual sea ...

Precaution

If any of following conditions are met,

keep engine idling with a/c on (engine

speed at less than 2000 rpm) for at least 1

minute:

Refrigerant gas has been refilled or a/c parts have

been replaced.

A long time has elapsed since the engine was

stopped.

Notice:

If the engine s ...

Dtc check / clear

Check dtc

Hint:

When dtc b1650/23 is detected as a result of

troubleshooting for the airbag system, troubleshoot

the occupant classification system.

Use the intelligent tester (with can vim) to read and

clear dtcs, otherwise the dtcs cannot be read and

cleared.

Connect ...