Toyota RAV4 (XA40) 2013-2018 Service Manual: Diagnosis system

- Description

- Air conditioning system data and the diagnostic trouble codes (dtcs) can be read through the data link connector 3 (dlc3) of the vehicle. When the system seems to be malfunctioning, use the intelligent tester to check for malfunctions and perform troubleshooting.

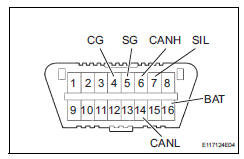

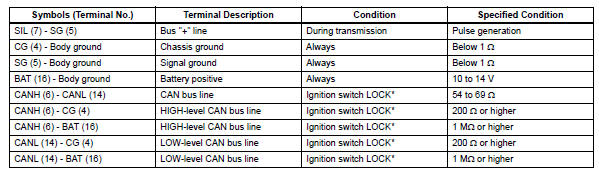

- Check dlc3

The vehicle's ecm uses the iso 15765-4 for communication protocol. The terminal arrangement of the dlc3 complies with sae j1962 and matches the iso 15765-4 format.

If the result is not as specified, the dlc3 may have a malfunction. Repair or replace the harness and connector.

Notice:

*: Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, other switches or doors.

Hint:

Connect the cable of the intelligent tester (with can vim) to the dlc3, turn the ignition switch on and attempt to use the tester. If the display indicates that a communication error has occurred, there is a problem either with the vehicle or with the tester.

If communication is normal when the tester is connected to another vehicle, inspect the dlc3 of the original vehicle.

If communication is still not possible when the tester is connected to another vehicle, the problem may be in the tester itself. Consult the service department listed in the tester's instruction manual.

Terminals of ecu (2006/01- )

Terminals of ecu (2006/01- )

Check air conditioning amplifier

Measure the voltage and resistance of the

connectors.

Hint:

Check from the rear of the connector while it is

connected to the air conditioning ampl ...

Dtc check / clear

Dtc check / clear

Check dtc

Connect the intelligent tester (with can vim) to the

dlc3.

Turn the ignition switch on and turn the intelligent

tester on.

Read the dtc by following the prompts on the

...

Other materials:

Throttle actuator control system

Description

The throttle actuator is operated by the ecm, and opens and closes the

throttle valve using gears. The

opening angle of the throttle valve is detected by the throttle position (tp)

sensor, which is mounted on

the throttle body. The tp sensor provides feedback to the ecm in ord ...

Installation (2005/11-2006/01)

Install abs and traction actuator assembly with bracket

Notice:

Do not remove the hole plug before connecting the

brake tube. New actuators are filled with brake fluid.

Install the actuator with bracket with the 3 nuts.

Torque: 19 n*m (194 kgf*cm, 14 ft.*Lbf)

Hint:

The nuts shou ...

Engine (ignition) switch

(vehicles with smart key

system)

Performing the following

operations when carrying

the electronic key on your

person starts the engine or

changes engine switch

modes.

Starting the engine

1. Pull the parking brake switch

to check that the parking

brake is set.

The parking brake indicator will

come on.

2. Check that the shift lever i ...