Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission system reference orifice

Dtc summary

Hint:

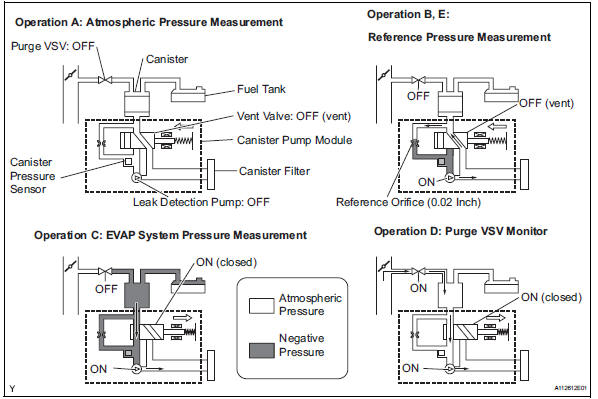

The reference orifice is located inside the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monitor description

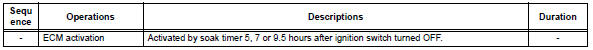

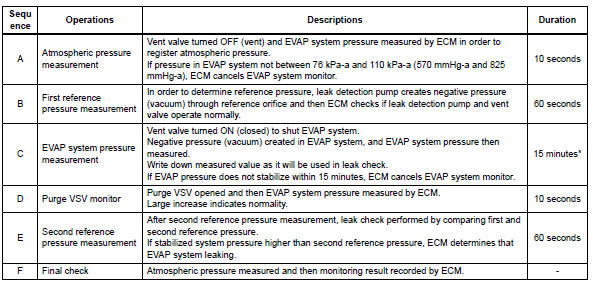

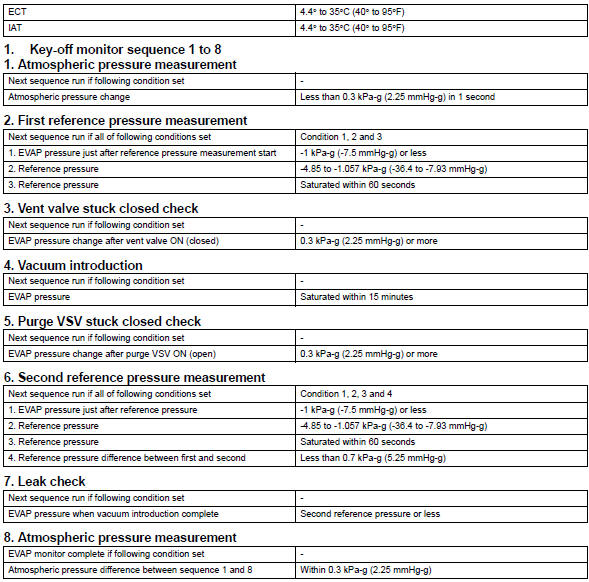

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 Hours later.

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

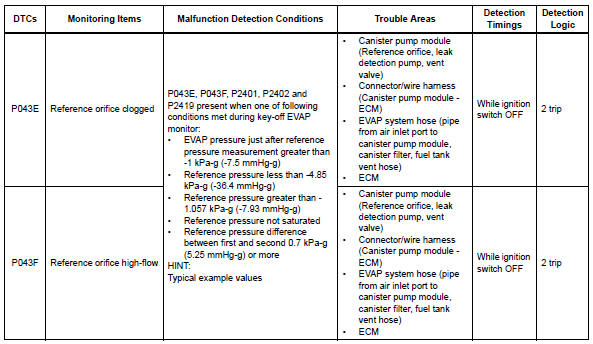

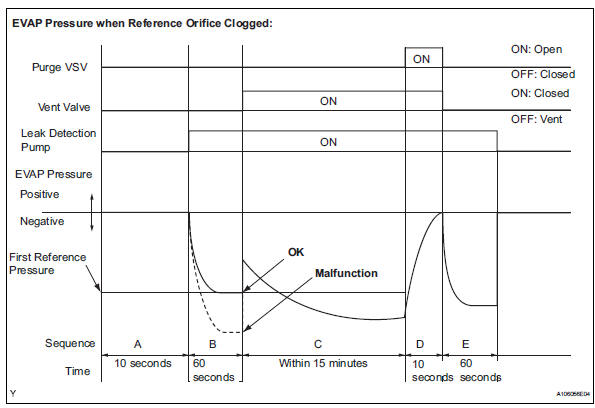

- P043e: reference orifice clogged

In operation b, the leak detection pump creates negative pressure (vacuum) through the reference orifice.

The evap system pressure is then measured by the ecm, using the canister pressure sensor, to determine the reference pressure. If the pressure is lower than -4.85 Kpa-g (-36.4 Mmhg-g), the ecm interprets this as a clog malfunction in the reference orifice, and stops the evap system monitor.

The ecm then illuminates the mil and sets the dtc (2 trip detection logic).

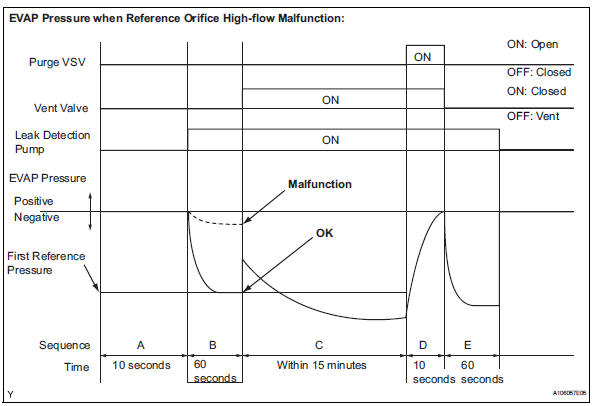

- P043f: reference orifice high-flow

In operation b, the leak detection pump creates negative pressure (vacuum) through the reference orifice.

The evap system pressure is then measured by the ecm using the canister pressure sensor to determine the reference pressure. If the pressure is higher than -1.057 Kpa-g (-7.93 Mmhg-g), the ecm interprets this as a high-flow malfunction in the reference orifice, and stops the evap system monitor. The ecm then illuminates the mil and sets the dtc (2 trip detection logic).

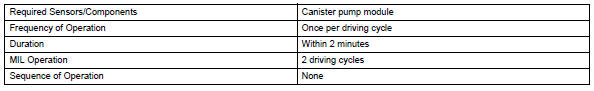

Monitor strategy

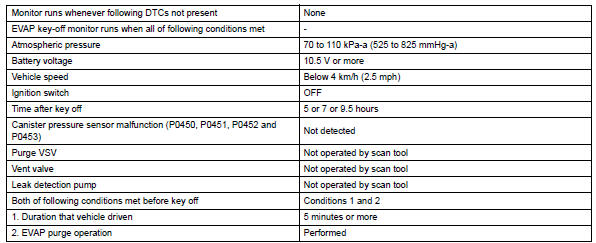

Typical enabling conditions

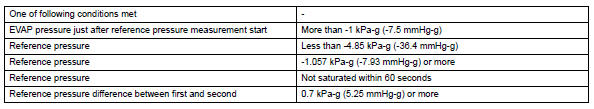

Typical malfunction thresholds

"Saturated" indicates that the evap pressure change is less than 0.286 Kpa-g (2.14 Mmhg-g) in 60 seconds.

Monitor result

Refer to checking monitor status (see page es-17).

Catalyst system efficiency below threshold (bank 1)

Catalyst system efficiency below threshold (bank 1)

Monitor description

The ecm uses sensors mounted in front of and behind the three-way catalytic

converter (twc) to

monitor its efficiency.

The first sensor, the air-fuel ratio (a/f) sensor, ...

Evaporative emission control system incorrect purge flow

Evaporative emission control system incorrect purge flow

Dtc summary

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monito ...

Other materials:

Diagnosis system

Description

Air conditioning system data and the diagnostic

trouble codes (dtcs) can be read through the

data link connector 3 (dlc3) of the vehicle. When

the system seems to be malfunctioning, use the

intelligent tester to check for malfunctions and

perform troubleshooting.

...

Precaution

Notice:

Perform the reset memory procedures (a/t

initialization) when replacing the automatic transaxle

assembly, engine assembly or ecm (see page ax-18).

Hint:

Reset memory cannot be completed by only reconnecting

the cable to the negative (-) battery terminal.

Caution:

When using compresse ...

Problem symptoms table (2006/01- )

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected area" column

of the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace p ...