Toyota RAV4 (XA40) 2013-2018 Service Manual: General maintenance (2005/11-2006/01)

- Inspect steering linkage and gear housing

- Check the steering wheel free play.

- Check the steering linkage for looseness or damage.

- Check that the tie rod ends do not have excessive play

- Check that the dust seals and boots are not damaged.

- Check that the boot clamps are not loose.

- Check that the steering gear housing is not damaged.

- Check that the connectors are properly connected to the steering gear housing.

- Inspect ball joints and dust covers

- Inspect the ball joints for excessive looseness.

- Jack up the front of the vehicle and place wooden blocks with a height of 180 to 200 mm (7.09 To 7.87 In.) Under the front tires.

- Lower the vehicle until the front coil spring has about half its ordinary load. Place stands under the vehicle for safety

- Check that the front wheels are pointing straight ahead. Use wheel chocks on all 4 wheels.

- Using a lever, pry up the end of the lower arm.

Check the amount of play.

Maximum ball joint vertical play: 0 mm (0 in.)

If there is any play, replace the ball joint.

- Check the dust cover for damage.

- Inspect drive shaft boots

- Check the drive shaft boots for loose clamps, grease leakage, kinks or damage.

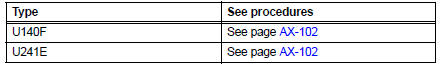

- Inspect automatic transaxle fluid level

- Visually check the transmission for fluid leakage. If

oil is leaking, find the cause and repair it.

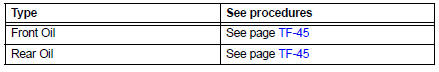

- Inspect transfer oil (for 4wd)

- Visually check the transfer for oil leakage. If oil is

leaking, find the cause and repair it.

- Inspect rear differential oil (for 4wd)

- For the rear differential oil inspection, refer to the following procedures (see page df-3).

- Rotate tires (see page tw-1)

Chassis

Chassis

...

General maintenance (2006/01- )

General maintenance (2006/01- )

Inspect steering linkage and gear housing

Check the steering wheel free play.

Check the steering linkage for looseness or

damage.

Check that the tie rod ends do not have

excessive ...

Other materials:

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and ...

Ecu malfunction

Description

Inspection procedure

If the power steering ecu detects these dtcs, it will shut off the motor

relay circuit (built into the power

steering ecu) and stop power assist. However, power assist continues if dtc

c1533 is output.

Reconfirm dtc

Check for dtc.

Ok:

dtc i ...

If the vehicle battery

is discharged

The following procedures may be used to start the engine if the

vehicle’s battery is discharged.

You can also call your toyota dealer or a qualified repair shop.

If you have a set of jumper (or booster) cables and a second vehicle

with a 12-volt battery, you can jump start your vehicle by fo ...