Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation

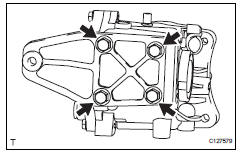

- Install rear differential support

- Install the differential support to the differential carrier with the 4 bolts.

Torque: 98 n*m (999 kgf*cm, 72 ft.*Lbf)

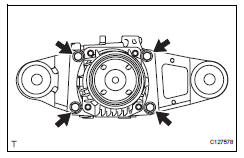

- Install rear differential no. 1 And no. 2 Support

- Install the differential no. 1 And no. 2 Supports with

the 4 bolts to the differential carrier.

Torque: 55 n*m (561 kgf*cm, 41 ft.*Lbf)

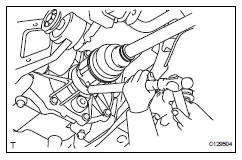

- Install rear differential carrier subassembly

- Support the rear differential carrier with a transmission jack or equivalent

- Apply hypoid gear oil to the splines of the left and right rear drive shaft inboard joints.

- Align the splines of the rear drive shaft inboard joints and, using a brass bar and hammer, tap in the left and right rear drive shafts.

Notice:

- Face the cutout section of the snap ring downward.

- Do not damage the oil seal during the insertion.

- Do not strike the tip of the outboard joint with the hammer.

Hint:

Determine whether or not the rear drive shaft is completely tapped in by checking for changes in sound or the reaction force of the brass bar.

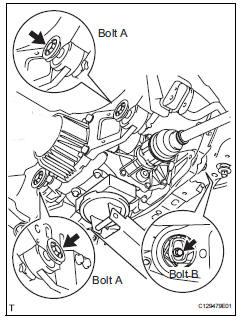

- Slowly raise the transmission jack, fix the nuts in place and install the 3 bolts.

Torque: 86 n*m (877 kgf*cm, 63 ft.*Lbf) for bolt a 140 n*m (1,428 kgf*cm, 103 ft.*Lbf) for bolt b

Notice:

Tighten the bolts, not the nuts.

- Connect the connector.

- Install the breather tube.

- Connect the harness clamp.

- Install rear suspension member brace lh

- Install the member brace to the suspension member with the 2 bolts.

Torque: 60 n*m (612 kgf*cm, 44 ft.*Lbf)

- Install rear suspension member brace rh

Hint:

Use the same procedures described for the lh side.

- Temporarily install propeller with center bearing shaft assembly (see page pr-5)

- Tighten propeller with center bearing shaft assembly (see page pr-6)

- Inspect joint angle (see page pr-4)

- Install center exhaust pipe assembly (see page ex-5)

- Install tailpipe assembly (see page ex-6)

- Install rear wheel torque: 103 n*m (1,050 kgf*cm, 76 ft.*Lbf)

- Add differential oil

- Add differential oil (see page df-3).

- Check for differential oil leakage

- Check for exhaust gas leakage

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

Reassembly

Reassembly

Install wiring harness clamp bracket

Install the bracket with the bolt.

Install elbow tube

Install straight pin

Using a plastic hammer, install the 4 straight pins to

the ...

Door lock

Door lock

...

Other materials:

Positioning a floor jack

When raising your vehicle with a floor jack, position the jack correctly.

Improper placement may damage your vehicle or cause

injury.

Front

Rear

Caution

When raising your vehicle

Make sure to observe the following precautions to reduce the possibility of

death or serious injury:

...

Components

...

Listening to an ipod

Connecting an ipod enables you to enjoy music from the vehicle

speakers.

Select “ipod” on the audio source selection screen.

When the ipod connected to the system includes ipod video, the

system can only output the sound by selecting the browse

screen.

Connecting an ipod

Audio control ...