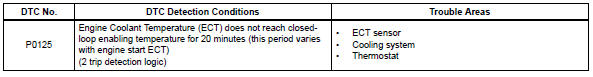

Toyota RAV4 (XA40) 2013-2018 Service Manual: Insufficient coolant temperature for closed loop fuel control

Description

Refer to dtc p0115 (see page es-105).

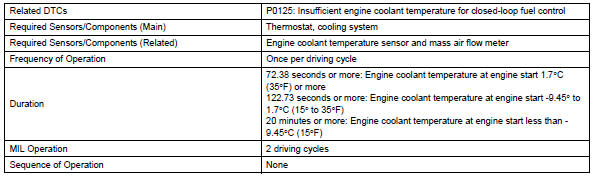

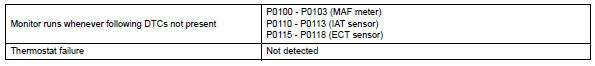

Monitor description

The resistance of the ect sensor varies in proportion to the actual ect. The ect supplies a constant voltage to the sensor and monitors the signal output voltage of the sensor. The signal voltage output varies according to the changing resistance of the sensor. After the engine is started, the ect is monitored through this signal. If the ect sensor indicates that the engine is not yet warm enough for closed-loop fuel control, despite a specified period of time having elapsed since the engine was started, the ecm interprets this as a malfunction in the sensor or cooling system and sets the dtc.

Example: the ect is 0°c (32°f) at engine start. After about 1 minute running time, the ect sensor still indicates that the engine is not warm enough to begin closed-loop fuel (air-fuel ratio feedback) control. The ecm interprets this as a malfunction in the sensor or cooling system and sets the dtc.

Monitor strategy

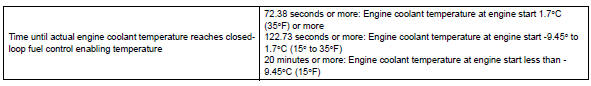

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0115 (see page es-106).

Inspection procedure

Hint:

- If any of dtcs p0115, p0116, p0117 or p0118 are set simultaneously with dtc p0125, the engine coolant temperature (ect) sensor may have an open or a short circuit. Troubleshoot those dtcs first.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

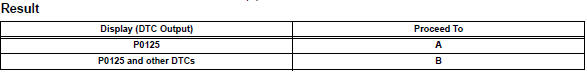

- Check any other dtcs output (in addition to dtc p0125)

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / dtc info / current codes.

- Read dtcs.

Hint:

If any dtcs other than p0125 are output, troubleshoot those dtcs first.

- Inspect thermostat

- Remove the thermostat (see page co-15).

- Check the valve opening temperature of the thermostat.

Standard value: 80 to 84°c (176 to 183°f)

Hint:

In addition to the above check, confirm that the valve is completely closed when the temperature is below the standard.

- Reinstall the thermostat (see page co-15).

- Check cooling system

- Check for defects in the cooling system that might cause the system to be too cold, such as abnormal radiator fan operation or any modifications.

Throttle / pedal position sensor / switch "A" circuit range / performance

problem

Throttle / pedal position sensor / switch "A" circuit range / performance

problem

Hint:

This dtc relates to the throttle position (tp) sensor.

Description

Refer to dtc p0120 (see page es-114).

Monitor description

The ecm uses the tp sensor to monitor the throttle valve ...

Coolant thermostat (coolant temperature below thermostat regulating

temperature)

Coolant thermostat (coolant temperature below thermostat regulating

temperature)

Hint:

This dtc relates to the thermostat.

Description

This dtc is set when the engine coolant temperature (ect) does not reach 75°c

(167°f) despite

sufficient engine warm-up time having el ...

Other materials:

High beam automatic turning on or off conditions

When all of the following conditions are fulfilled, high beam will be

automatically turned on:

Vehicle speed is above approximately 21 mph (34 km/h).

The area ahead of the vehicle is dark.

There are no oncoming or preceding vehicles with headlights or tail

lights turned on.

There are fe ...

Installation

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

When installing the moulding, heat the vehicle body and

moulding using a heat light.

Standard heating temperature

Notice:

Do not heat the vehicle body and moulding

excessively ...

Propeller shaft assembly

Components

Removal

Remove propeller shaft with center bearing

shaft assembly

Remove the 2 bolts and 2 adjusting washers, and

disconnect the propeller with center bearing shaft.

Notice:

During the removal, do not exert excessive

force on the universal joint.

When r ...