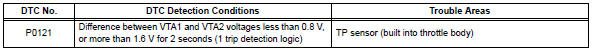

Toyota RAV4 (XA40) 2013-2018 Service Manual: Throttle / pedal position sensor / switch "A" circuit range / performance problem

Hint:

This dtc relates to the throttle position (tp) sensor.

Description

Refer to dtc p0120 (see page es-114).

Monitor description

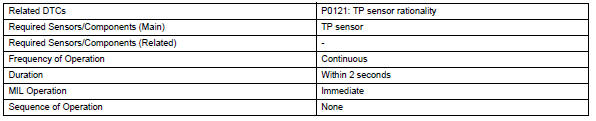

The ecm uses the tp sensor to monitor the throttle valve opening angle.

This sensor transmits two signals: vta1 and vta2. Vta1 is used to detect the throttle opening angle and vta2 is used to detect malfunctions in vta1. The ecm performs several checks to confirm the proper operation of the tp sensor and vta1.

For each throttle opening angle, a specific voltage difference is expected between the outputs of vta1 and vta2. If the output voltage difference between the two signals deviates from the normal operating range, the ecm interprets this as a malfunction of the tp sensor. The ecm illuminates the mil and sets the dtc.

If the malfunction is not repaired successfully, the dtc is set 2 seconds after the engine is next started.

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

![]()

Fail-safe

When this dtc, as well as other dtcs relating to etcs (electronic throttle control system) malfunctions, is set, the ecm enters fail-safe mode. During fail-safe mode, the ecm cuts the current to the throttle actuator off, and the throttle valve is returned to a 6° throttle angle by the return spring. The ecm then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a minimal speed. If the accelerator pedal is depressed firmly and gently, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

Inspection procedure

Hint:

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

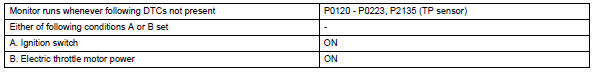

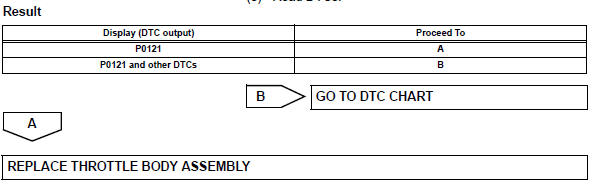

- Check any other dtcs output (in addition to dtc p0121)

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / dtc info / current codes.

- Read dtcs.

Throttle / pedal position sensor / switch "A"

Throttle / pedal position sensor / switch "A"

Hint:

These dtcs relate to the throttle position (tp) sensor.

Description

The tp sensor is mounted on the throttle body, and detects the opening angle

of the throttle valve. This

sensor is a ...

Insufficient coolant temperature for closed loop fuel control

Insufficient coolant temperature for closed loop fuel control

Description

Refer to dtc p0115 (see page es-105).

Monitor description

The resistance of the ect sensor varies in proportion to the actual ect. The

ect supplies a constant

voltage to the ...

Other materials:

Identification information

Vehicle identification and serial numbers

Vehicle identification number

The vehicle identification number is stamped on the

vehicle identification number plate and on the

certification label, as shown in the illustrations.

Vehicle identification number plate

Certification label ...

Installation

Install starter assembly

Install the starter with the 2 bolts.

Torque: 37 n*m (377 kgf*cm, 27 ft.*Lbf)

Connect the starter connector.

Install the terminal nut and cover the nut with the

cap.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*Lbf)

Install battery bracket reinfor ...

Stop & Start system

The Stop & Start system

stops and starts the engine

according to brake pedal or

shift lever operation when

the vehicle is stopped, such

as at a stoplight, intersection,

etc., in order to

improve fuel economy and

reduce noise pollution

caused by the engine idling.

Stop & Start system operatio ...