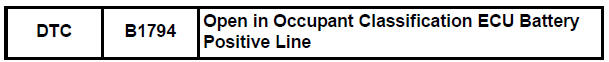

Toyota RAV4 (XA40) 2013-2018 Service Manual: Open in occupant classification ecu battery positive line

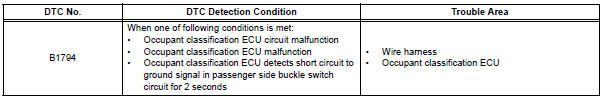

Description

Dtc b1794 is set when a malfunction is detected in the occupant classification ecu battery positive line.

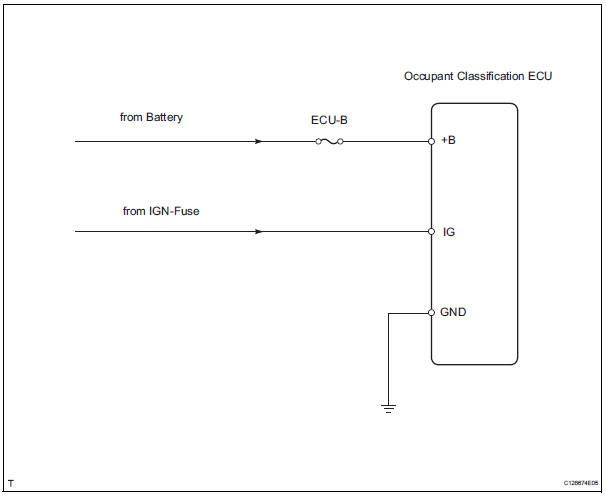

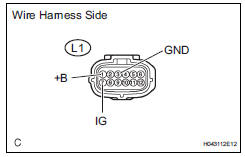

Wiring diagram

Inspection procedure

- Check for dtc

- Turn the ignition switch on.

- Clear the dtcs (see page rs-249).

Hint:

First clear dtcs stored in the occupant classification ecu and then in the center airbag sensor.

- Turn the ignition switch off, and wait for at least 10 seconds.

- Turn the ignition switch on.

- Check the dtcs (see page rs-249).

Ok: dtc b1794 is not output.

Hint:

Dtcs other than b1794 may be output at this time, but they are not related to this check.

- Check connection of connector

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Check that the connectors are properly connected to the occupant classification ecu.

Ok: the connectors are properly connected.

- Check wire harness (source voltage)

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Disconnect the l1 connector from the occupant classification ecu.

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Measure the voltage of the wire harness side connector.

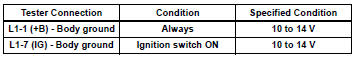

Standard voltage

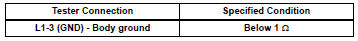

- Measure the resistance of the wire harness side connector.

Standard resistance

- Check for dtc

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Connect the connectors to the occupant classification ecu.

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Turn the ignition switch on.

- Clear the dtcs (see page rs-249).

Hint:

First clear dtcs stored in the occupant classification ecu and then in the center airbag sensor.

- Turn the ignition switch off, and wait for at least 10 seconds.

- Turn the ignition switch on.

- Using the intelligent tester, check for dtcs of the occupant classification ecu (see page rs-249).

Ok: dtc b1794 is not output.

Hint:

Dtcs other than b1794 may be output at this time, but they are not related to this check.

- Replace occupant classification ecu

- Turn the ignition switch off.

- Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

- Replace the occupant classification ecu (see page rs- 392).

Hint:

Perform the inspection using parts from a normal vehicle when possible.

- Perform zero point calibration

- Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

- Connect the intelligent tester (with can vim) to the dlc3.

- Turn the ignition switch on.

- Using the intelligent tester, perform the zero point calibration (see page rs-241).

Ok: completed is displayed.

- Perform sensitivity check

- Using the intelligent tester, perform the sensitivity check (see page rs-241).

Standard value: 27 to 33 kg (59.52 To 72.75 Lb)

End

Occupant classification sensor power supply circuit malfunction

Occupant classification sensor power supply circuit malfunction

Description

The occupant classification sensor power supply circuit consists of the

occupant classification ecu and

the occupant classification sensors.

Dtc b1793 is recorded when a malfunc ...

Occupant classification ecu malfunction

Occupant classification ecu malfunction

Description

Dtc b1795 is recorded when a malfunction is detected in the occupant

classification ecu.

Troubleshoot dtc b1771 first when dtc b1771 and b1795 are output simultaneously.

Wir ...

Other materials:

Open in one side of can branch line

Description

If 2 or more ecus and/or sensors do not appear on the intelligent tester's

"bus check" screen via the

can vim, one side of the can branch wire may be open. (One side of the canh

[branch wire] /canl

[branch wire] of the ecu and/or sensor is open.)

Wiring diagram

...

Fog light switch

The fog lights secure excellent visibility in difficult driving

conditions,

such as in rain and fog.

(U.S.A.) Or (canada)

turns the fog lights off

Turns the fog lights on

Fog lights can be used when

The headlights are on in low beam. ...

Components

...