Toyota RAV4 (XA40) 2013-2018 Service Manual: Reassembly

- Install generator rotor assembly

- Install the washer onto the generator rectifier end frame.

- Install the generator rotor onto the generator rectifier end frame.

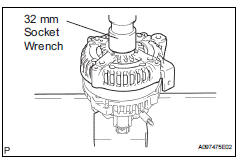

- Using a 32 mm socket wrench and press, slowly push the generator drive end frame onto the generator rectifier end frame.

- Tighten the 4 bolts.

Torque: 5.8 N*m (59 kgf*cm, 51 in.*Lbf)

- Install the cord clip with the bolt.

Torque: 4.6 N*m (47 kgf*cm, 41 in.*Lbf)

- Install generator brush holder assembly

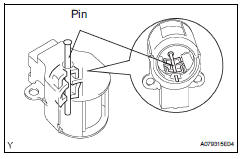

- While pushing the 2 brushes into the generator brush holder, insert a 1.0 Mm (0.039 In.) Pin into the generator brush holder.

- Install the generator brush holder with the 2 screws.

Torque: 1.8 N*m (18 kgf*cm, 16 in.*Lbf)

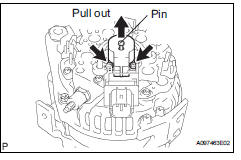

- Pull the pin out of the generator brush holder.

- Install the terminal insulator onto the generator rectifier end frame.

- Install the generator rear end cover with the 3 nuts.

Torque: 4.6 N*m (47 kgf*cm, 41 in.*Lbf)

Install generator pulley with clutch

- Install the pulley by hand.

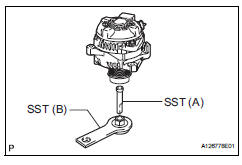

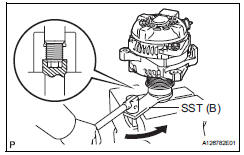

- Install sst to the pulley and vise as shown in the illustration.

Sst 09820-63020

- Turn sst (b) counterclockwise to tighten the pulley.

Torque: 111 n*m (1125 kgf*cm, 81 ft.*Lbf)

- Install a new cap to the pulley.

- Check that the generator pulley rotates smoothly.

Replacement

Replacement

Replace generator drive end frame bearing

Remove the 4 screws and bearing retainer.

Using sst and a hammer, tap out the bearing.

Sst 09950-60010 (09951-00250), 09950-70010

(0995 ...

Installation

Installation

Install generator assembly

Confirm that the wire harness of the crankshaft

position sensor is secured to the wire harness

clamp bracket through the back of the rib of the

timing cha ...

Other materials:

Disassembly

Hint:

When removing the ornament plate and emblem, heat the

radiator grille, ornament plate and emblem using a heat light.

Standard heating temperature

Notice:

Do not heat the radiator grille, ornament plate and

emblem excessively.

Remove hood to radiator grille seal

Remove th ...

Rear coil spring

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove rear wheel

Remove skid control sensor wire (for 2wd)

(see page bc-198)

Remove rear speed sensor lh (for 4wd) (see

page bc-205)

Disconnect ...

Problem symptoms table (2006/01- )

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected area" column

of the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace p ...