Toyota RAV4 (XA40) 2013-2018 Service Manual: Speed sensor

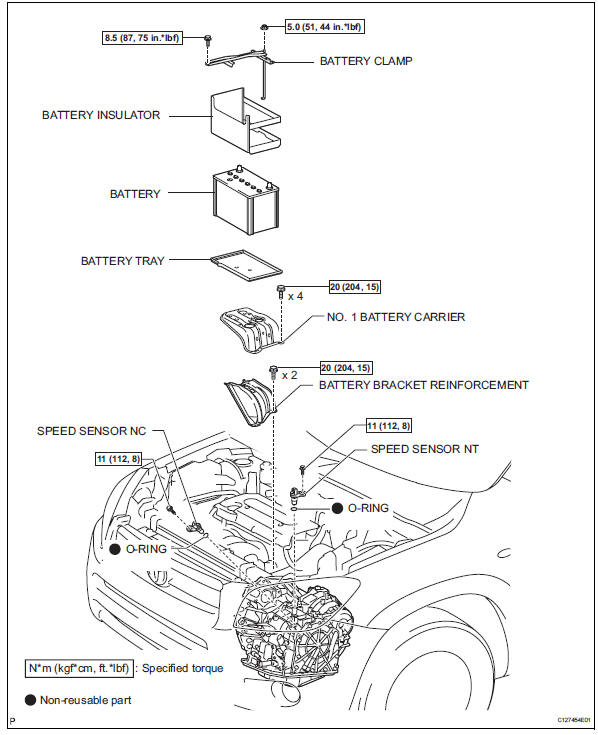

Components

Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove battery

- Loosen the nut and remove the bolt and battery clamp.

- Remove the battery.

- Remove the battery tray.

- Remove the 4 bolts and battery carrier.

- Remove the 2 bolts and battery bracket reinforcement.

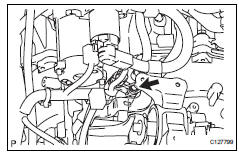

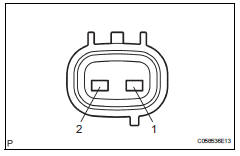

- Remove speed sensor nt

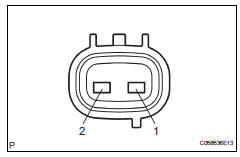

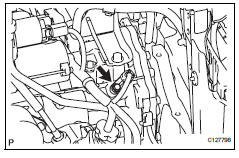

- Disconnect the sensor connector.

- Remove the bolt and sensor.

- Remove the o-ring from the sensor.

- Remove speed sensor nc

- Disconnect the sensor connector.

- Remove the bolt and sensor.

- Remove the o-ring from the sensor.

Inspection

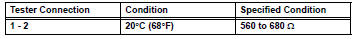

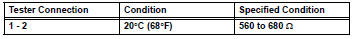

- Inspect speed sensor nt

Measure the resistance of the sensor.

Standard resistance

- Inspect speed sensor nc

Measure the resistance of the sensor.

Standard resistance

Installation

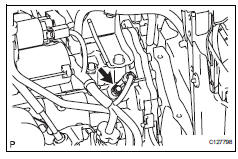

- Install speed sensor nc

- Coat a new o-ring with atf.

- Install the o-ring to the sensor.

- Install the sensor with the bolt.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

- Connect the sensor connector.

- Install speed sensor nt

- Coat a new o-ring with atf.

- Install the o-ring to the sensor.

- Install the sensor with the bolt.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

- Connect the sensor connector.

- Install battery

- Install the battery bracket reinforcement with the 2 bolts.

Torque: 20 n*m (204 kgf*cm, 15 ft.*Lbf)

- Install the battery carrier with the 4 bolts.

Torque: 20 n*m (204 kgf*cm, 15 ft.*Lbf)

- Install the battery tray.

- Install the battery with the battery clamp.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*Lbf) for bolt

5.0 N*m (51 kgf*cm, 44 in.*Lbf) for nut

- Connect cable to negative battery terminal

Automatic transaxle fluid

Automatic transaxle fluid

On-vehicle inspection

Check transaxle fluid level

Hint:

Drive the vehicle so that the engine and transaxle are at

normal operating temperature.

Fluid temperature:

70 to 80¬įc (158 to 176¬įf ...

Transmission wire

Transmission wire

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

preven ...

Other materials:

System too

Description

The fuel trim is related to the feedback compensation value, not to the basic

injection time. The fuel trim

consists of both the short-term and the long-term fuel trims.

The short-term fuel trim is fuel compensation that is used to constantly

maintain the air-fuel ratio at

...

Dtc check / clear

Check dtc (using intelligent tester)

Connect the intelligent tester (with can vim) to the

dlc3.

Turn the ignition switch on.

Read the dtcs by following the directions on the

tester screen.

Hint:

Refer to the intelligent tester operator's manual for

further details.

Chec ...

Instrument cluster

For the purpose of explanation, the following illustrations display all

warning lights and indicators illuminated.

‚Ė† With 7-inch multi-information display

The display of the speedometer can be selected from two types,

analog or digital.

When analog speedometer is displayed

The units used on the m ...