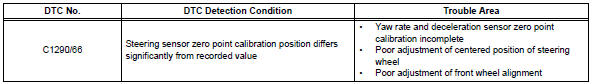

Toyota RAV4 (XA40) 2013-2018 Service Manual: Steering angle sensor zero point malfunction

![]()

Description

The skid control ecu learns the steering sensor zero point every time the ignition switch is turned on and the vehicle is driven at 35 km/h (22 mph) or more for approximately 5 seconds. The ecu also stores the previous zero point.

If front wheel alignment or the steering wheel position is adjusted without disconnecting the negative battery terminal, or if the yaw rate and deceleration sensor zero point is not set after the adjustments have been completed, the skid control ecu detects the difference between the previously stored zero point and the newly learned zero point and outputs this dtc to indicate a poor adjustment.

Indication of the steering sensor zero point malfunction is canceled by turning the ignition switch off.

Inspection procedure

Notice:

When replacing the abs and traction actuator, perform zero point calibration (see page bc-24).

- Perform yaw rate and deceleration sensor zero point calibration

- Perform the zero point calibration of the yaw rate and deceleration sensor (see page bc-24).

Hint:

- When the stored zero point of the yaw rate and deceleration sensor is erased, the steering sensor zero point is also erased.

- If the zero point and output value of the yaw rate and deceleration sensor and the output values of the speed sensors are not normal, the steering sensor zero point cannot be learned normally even if the vehicle is driven straight ahead at 35 km/h (22 mph) or more.

- Check steering sensor

- Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more.

- Check that the centered position of the steering wheel is correctly set while driving straight ahead.

Hint:

If the front wheel alignment and steering position are adjusted due to an incorrectly centered position of the steering wheel, set the yaw rate and deceleration sensor zero point again after the adjustments are completed.

Ok: the center position of the steering wheel is correctly set.

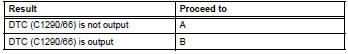

- Reconfirm dtc

- Turn the ignition switch off.

- Clear the dtc (see page bc-47).

- Check if the same dtc is recorded (see page bc-47).

Result

Use simulation method to check

Brake pedal load sensing switch

Brake pedal load sensing switch

Description

The brake pedal load sensing switch is turned on when the brake pedal is

depressed with force exceeding

a predetermined level.

The skid control ecu detects if the brake pedal is dep ...

Different diameter tire malfunction

Different diameter tire malfunction

Description

The skid control ecu measures the speed of each wheel by receiving signals

from the speed sensor.

These signals are used for recognizing that all 4 wheels are operating properly. ...

Other materials:

System description

Brief description

The can (controller area network) is a serial data

communication system for real time application. It is

a vehicle multiplex communication system which

has a high communication speed (500 kbps) and

the ability to detect malfunctions.

By pairing the canh and canl ...

Utility vehicle precautions

This vehicle belongs to the

utility vehicle class, which

has higher ground clearance

and narrower tread in

relation to the height of its

center of gravity to make it

capable of performing in a

wide variety of off-road

applications.

Utility vehicle feature

Specific design characteristics

give it a ...

Precaution

Troubleshooting precaution

When there are malfunctions in the contact points of

the terminals or installation problems with any parts,

removal and installation of the suspected problem

parts may return the system to its normal condition

either entirely or temporarily.

In order to ...