Toyota RAV4 (XA40) 2013-2018 Service Manual: Symptom simulation

Hint:

The most difficult case in troubleshooting is when no problem symptoms occur. In such a case, a thorough problem analysis must be carried out. A simulation of the same or similar conditions and environment in which the problem occurred in the customer's vehicle should be carried out. No matter how much skill or experience a technician has, troubleshooting without confirming the problem symptoms will lead to important repairs being overlooked and mistakes or delays.

For example:

With a problem that only occurs when the engine is cold or as a result of vibration caused by the road during driving, the problem can never be determined if the symptoms are being checked on a stationary vehicle or on a vehicle with a warmedup engine. Vibration, heat or water penetration (moisture) is difficult to reproduce. The symptom simulation tests below are effective substitutes for the conditions and can be applied on a stationary vehicle.

Important points in the symptom simulation test: in the symptom simulation test, the problem symptoms as well as the problem area or parts must be confirmed. First, narrow down the possible problem circuits according to the symptoms. Then, connect the tester and carry out the symptom simulation test, judging whether the circuit being tested is defective or normal. Also, confirm the problem symptoms at the same time.

Refer to the problem symptoms table for each system to narrow down the possible causes.

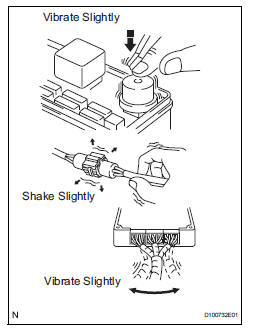

- Vibration method:

When a malfunction seems to occur as a result of vibration.

- Part and sensor

Apply slight vibration with a finger to the part of the sensor suspected to be the cause of the problem, and check whether or not the malfunction occurs.

Notice:

Applying strong vibration to relays may open them.

- Connectors

Slightly shake the connector vertically and horizontally.

- Wire harness

Slightly shake the wire harness vertically and horizontally.

Hint:

The connector joint and fulcrum of the vibration are the major areas that should be checked thoroughly.

- Heat method:

When a malfunction seems to occur when the area in question is heated.

- Heat the component that is the possible cause of the malfunction with a hair dryer or similar device. Check if the malfunction occurs.

Notice:

Do not heat to more than 60°c (140°f).

Exceeding this temperature may damage components.

- Do not apply heat directly to the parts in the ecu.

- Water sprinkling method:

When a malfunction seems to occur on a rainy day or in high-humidity.

- Sprinkle water onto the vehicle and check if the malfunction occurs.

Notice:

- Never sprinkle water directly into the engine compartment. Indirectly change the temperature and humidity by spraying water onto the front of the radiator.

- Never apply water directly onto the electronic components.

Hint:

If the vehicle has or had a water leakage problem, the leakage may have damaged the ecu or connections. Look for evidence of corrosion or short circuits. Proceed with caution during water tests.

- High electrical load method:

When a malfunction seems to occur when the electrical load is excessive.

- Turn on the heater blower, headlight, rear

window defogger and all other electrical loads.

Check if the malfunction reoccurs.

Symptom confirmation and diagnostic trouble code

Symptom confirmation and diagnostic trouble code

Hint:

The diagnostic system in the rav4 has various

functions.

The first function is the diagnostic trouble code

(dtc) check. A dtc is a code stored in the ecu

memory whenever a malfunction ...

Diagnostic trouble code chart

Diagnostic trouble code chart

Look for output diagnostic trouble codes (dtcs) (from the

dtc checks) in the appropriate section's diagnostic trouble

code chart. Use the chart to determine the trouble area and

the proper inspecti ...

Other materials:

Headlight assembly

Components

Removal

Hint:

Use the same procedures for the rh and lh sides.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Remove front fender liner lh (see page et-4)

Remove front fender liner rh (see page et-4)

Remove ra ...

Cargo and luggage

Take notice of the following

information about storage

precautions, cargo capacity

and load.

WARNING

â– Things that must not be carried

in the luggage compartment

The following things may cause a

fire if loaded in the luggage compartment:

Receptacles containing gasoline

Aerosol cans

â– Storage p ...

Seat heater system

Parts location

System diagram

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected area" column

of the table. Check each symptom by check ...