Toyota RAV4 (XA40) 2013-2018 Service Manual: Valve body assembly

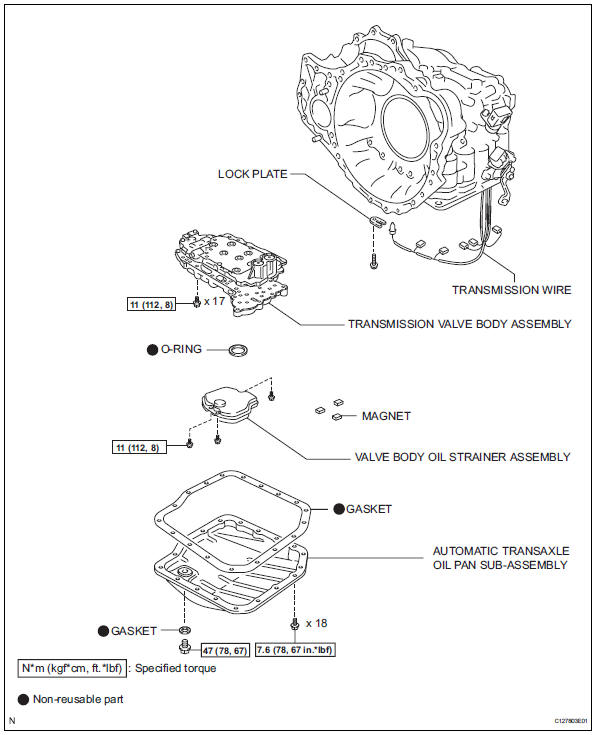

Components

Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove no. 1 Engine under cover

- Drain automatic transaxle fluid

- Remove the drain plug and gasket, and drain atf.

- Install a new gasket and the drain plug.

Torque: 47 n*m (479 kgf*cm, 35 ft.*Lbf)

- Remove automatic transaxle oil pan subassembly

- Remove the 18 bolts, oil pan and gasket.

Notice:

Some fluid will remain in the oil pan. Carefully remove the oil pan sub-assembly.

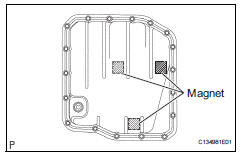

- Remove the 3 magnets from the oil pan.

- Examine particles in the pan.

- Use the removed magnets to collect any steel

chips. Look carefully at the chips and particles

in the pan and on the magnet to anticipate what

type of wear you will find in the transaxle.

Steel (magnetic): bearing, gear and plate wear brass (non-magnetic): bush wear

- Remove valve body oil strainer assembly

- Remove the 3 bolts and oil strainer.

Notice:

Be careful as some fluid will come out with the oil strainer.

- Remove the o-ring from the oil strainer.

- Disconnect transmission wire

- Disconnect the 5 connectors.

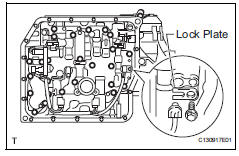

- Remove the bolt and lock plate, and remove the atf temperature sensor.

- Remove transmission valve body assembly

- Support the valve body and remove the 17 bolts and valve body.

Notice:

Be careful not to drop the check valve body, spring and accumulator piston.

- Remove the check ball body and spring.

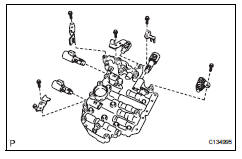

- Remove the 5 bolts, 4 plates and 5 shift solenoid valves.

Installation

- Install transmission valve body assembly

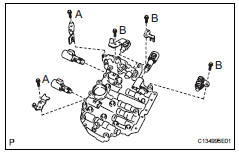

- Install the 5 shift solenoid valves with the 5 bolts and 4 plates.

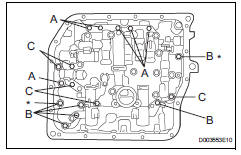

Torque: 6.6 N*m (67 kgf*cm, 58 in.*Lbf) for bolt a 11 n*m (112 kgf*cm, 8 ft.*Lbf) for bolt b

Hint:

Each bolt length is indicated below.

Bolt length:

12 Mm (0.47 In.) For bolt a

45 Mm (1.77 In.) For bolt b

- Install the spring and check ball body.

- Align the groove of the manual valve with the pin of lever

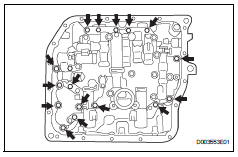

- Install the 17 bolts.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

Notice:

- Push the valve body against the accumulator piston spring and the check ball body to install it.

- Tighten the bolts marked by * in the illustration first temporarily because they are positioning bolts.

Hint:

Each bolt length is indicated below.

Bolt length:

25 Mm (0.984 In.) For bolt a

41 Mm (1.614 In.) For bolt b

45 Mm (1.771 In.) For bolt c

- Install transmission wire

- Coat the o-ring of the temperature sensor with atf.

- Install the atf temperature sensor with the lock plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*Lbf)

- Connect the 5 shift solenoid valve connectors.

- Install valve body oil strainer assembly

- Coat a new o-ring with atf.

- Install the o-ring to the oil strainer.

- Install the oil strainer with the 3 bolts.

Torque: 11 n*m (112 kgf*cm, 8 ft.*Lbf)

- Install automatic transaxle oil pan subassembly

- Install the 3 magnets in the oil pan.

- Install a new gasket and oil pan with the 18 bolts.

Torque: 7.6 N*m (77 kgf*cm, 67 in.*Lbf)

- Install no. 1 Engine under cover

- Connect cable to negative battery terminal

- Add automatic transaxle fluid

Fluid type: toyota genuine atf ws

- Inspect transaxle fluid level

- Inspect the fluid level (see page ax-102).

- Perform reset memory

- Perform the reset memory procedures (a/t initialization) (see page ax-18).

Transmission wire

Transmission wire

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

preven ...

Shift lock system

Shift lock system

Parts location

System diagram

On-vehicle inspection

Check shift lock operation

Move the shift lever to p.

Turn the ignition switch off.

Check that the shift lever cannot be mov ...

Other materials:

Open in abs solenoid relay circuit

Description

The solenoid relay supplies power to the abs solenoid and trc solenoid.

After the ignition switch is turned on, the vehicle speed has reached 6 km/h (4

mph) and the solenoid is

determined to be normal by the initial check self-diagnosis, the relay switches

on. If any open or ...

Short in driver side squib circuit

Description

The driver side squib circuit consists of the center airbag sensor, the

spiral cable and the steering pad.

The circuit instructs the srs to deploy when the deployment conditions are met.

These dtcs are recorded when a malfunction is detected in the driver side squib

circui ...

Can communication system

Precaution

Precaution

Turn the ignition switch off before measuring the

resistance of the main wire and the branch wire.

After the ignition switch is turned off, check that the

key reminder warning system and light reminder

warning system are not in operation.

Before measuring th ...