Toyota RAV4 (XA40) 2013-2018 Service Manual: Basic inspection

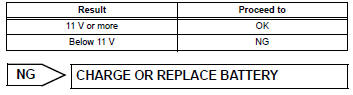

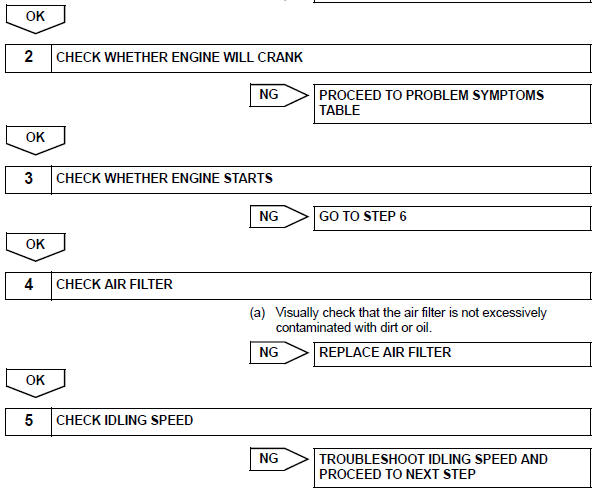

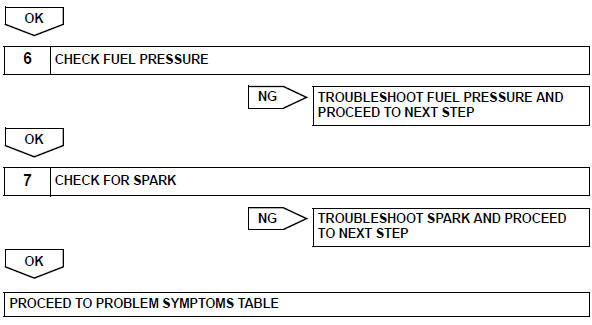

When a malfunction is not confirmed by the dtc check, troubleshooting should be carried out in all circuits considered to be possible causes of the problem. In many cases, by carrying out the basic engine check shown in the following flowchart, the location of the problem can be found quickly and efficiently. Therefore, using this check is essential when engine troubleshooting.

![]()

Notice:

Conduct this check with the engine stopped and ignition

switch off.

Check for intermittent problems

Check for intermittent problems

Hint:

Inspect the vehicle's ecm using check mode. Intermittent

problems are easier to detect with the intelligent tester when

the ecm is in check mode. In check mode, the ecm uses 1

trip detection ...

Registration

Registration

Notice:

The vehicle identification number (vin) must be input

into the replacement ecm.

Hint:

The vin is a 17-digit alphanumeric number. The intelligent

tester is required to register the vin.

...

Other materials:

Removal

Caution:

Be sure to read the precautionary notices concerning the

srs airbag system before servicing it (see page rs-1).

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent air ...

Registering a bluetooth®

audio player for the

first time

To use the bluetooth® audio, it is necessary to register an audio

player with the system.

Once the player has been registered, it is possible to use the

bluetooth® audio.

For details about registering a bluetooth® device

Turn the bluetooth® connection setting of your audio player on. ...

Warning lights and indicators

The warning lights and indicators on the instrument cluster and

center panel inform the driver of the status of the vehicle’s various

systems.

For the purpose of explanation, the following illustration displays

all warning lights and indicators illuminated.

Instrument cluster

Some indi ...