Toyota RAV4 (XA40) 2013-2018 Service Manual: Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove radiator support opening cover

- Remove front wheel rh

- Remove no. 1 Engine under cover

- Remove front fender apron rh

- Remove no. 1 Engine cover

- Remove the 2 nuts and cover

- Drain engine oil (see page lu-4)

- Remove front exhaust pipe (see page ex-3)

- Remove front suspension member reinforcement rh (see page em-6)

- Remove fan and generator v belt (see page em-6)

- Remove generator assembly (see page ch-9)

- Remove radiator reservoir

- Remove the 2 bolts and radiator reservoir.

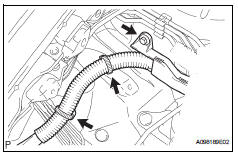

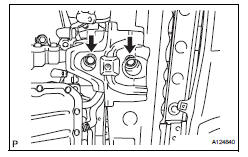

- Remove engine mounting insulator rh

- Remove the bolt of the wire harness protector.

- Disconnect the 2 clamps of the engine wire.

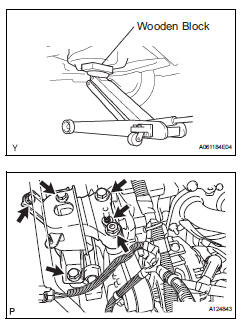

- Place a transmission jack underneath the engine, then put a wooden block on the jack.

- Remove the 4 bolts, 2 nuts and engine mounting insulator rh.

Notice:

Do not apply excessive force to the return tube when removing the engine mounting insulator rh.

Hint:

Keep clearance by lowering the engine using the transmission jack when removing the engine mounting insulator fr.

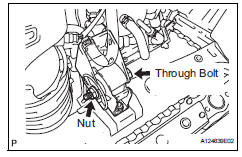

- Remove engine mounting insulator fr

- Remove the through bolt and nut.

- Remove the 2 bolts and engine mounting insulator fr.

Hint:

Keep clearance by lowering the engine using the transmission jack when removing the engine mounting insulator fr.

- Remove idler pulley

- Loosen the 2 bolts and remove the idler pulley with the 2 bolts.

- Remove ignition coil assembly (see page ig-9)

- Remove spark plug (see page em-8)

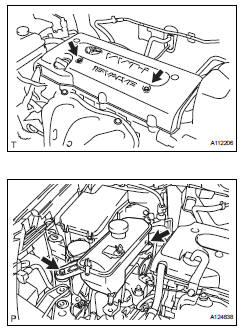

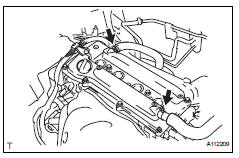

- Remove cylinder head cover sub-assembly

- Disconnect the 2 ventilation hoses form the cylinder head cover.

- Remove the 2 bolts and disconnect the 2 engine wires.

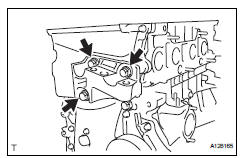

- Remove the 8 bolts, 2 nuts and cylinder head cover.

- Remove oil pan sub-assembly

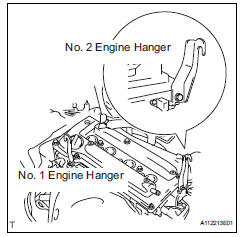

- Install the no. 1 And no. 2 Engine hangers with the bolts.

Torque: 38 n*m (387 kgf*cm, 28 ft.*Lbf)

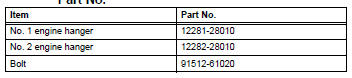

part no.

- Attach the sling device to the engine hangers and chain block.

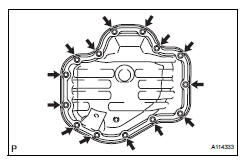

- Remove the 12 bolts and 2 nuts.

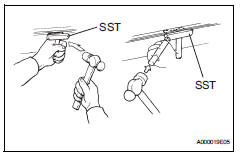

- Insert the blade of sst between the crankcase, chain cover and oil pan, then cut off the applied sealer and remove the oil pan.

Sst 09032-00100

Notice:

Be careful not to damage the contact surface of the crankcase, chain cover and oil pan.

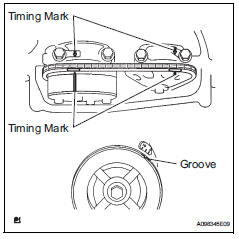

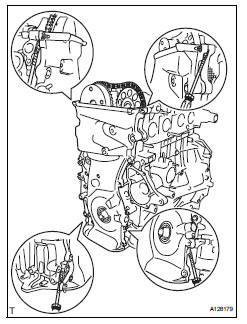

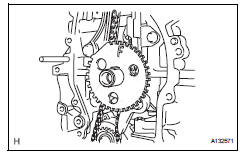

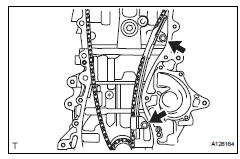

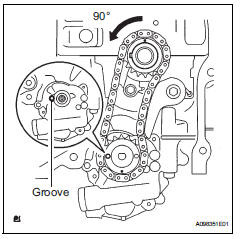

- Set no. 1 Cylinder to tdc/compression

- Turn the crankshaft pulley until its groove and the timing mark "0" of the timing chain cover are aligned.

- Check that each timing mark of the camshaft timing

gear and sprocket is aligned with each timing mark

located on the no. 1 And no. 2 Bearing caps as

shown in the illustration.

If not, turn the crankshaft by 1 revolution (360°) to align the timing marks as above.

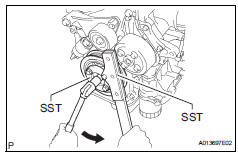

- Remove crankshaft pulley

- Using sst, fix the pulley in place and loosen the pulley bolt.

Sst 09213-54015 (91651-60855), 09330-00021

- Remove the crankshaft pulley.

Hint:

If necessary, remove the pulley and pulley bolt using sst.

Sst 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021), 09950-40011 (09957-04010)

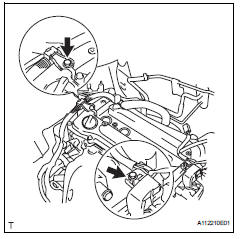

- Remove no. 1 Chain tensioner assembly

- Remove the 2 nuts, chain tensioner and gasket.

Notice:

Do not turn the crankshaft without the chain tensioner.

- Remove engine mounting bracket rh

- Remove the 3 bolts and engine mounting bracket rh.

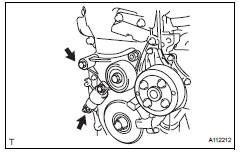

- Remove v-ribbed belt tensioner assembly

- Lift the engine upward using the transmission jack.

Notice:

Do not lift the engine more than necessary.

- Remove the bolt, nut and v-ribbed belt tensioner.

- Remove crankshaft position sensor (see page es-402)

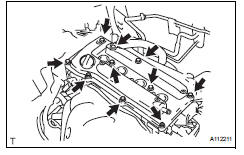

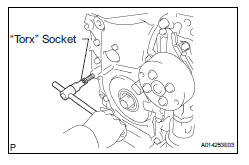

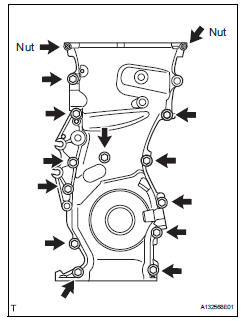

- Remove timing chain cover sub-assembly

- Using an e10 "torx" socket, remove the stud bolt for the v-ribbed belt tensioner.

- Remove the 12 bolts and 2 nuts.

- Remove the timing chain cover by prying the portions between the timing chain cover, cylinder head and cylinder block with a screwdriver.

Notice:

Be careful not to damage the contact surfaces of the timing chain cover, cylinder head and cylinder block.

- Remove no. 1 Crankshaft position sensor plate

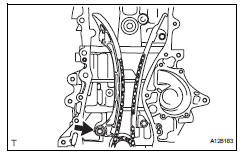

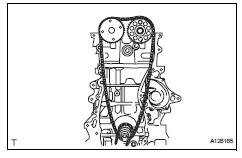

- Remove timing chain guide

- Remove the bolt and timing chain guide.

- Remove chain tensioner slipper

- Remove the bolt and chain tensioner slipper.

- Remove no. 1 Chain vibration damper

- Remove the 2 bolts and chain vibration damper.

- Remove chain sub-assembly

- Remove crankshaft timing sprocket

- Remove no. 2 Chain sub-assembly

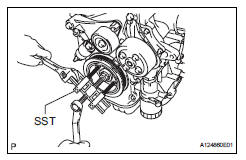

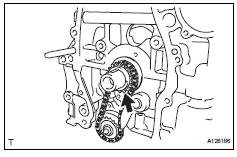

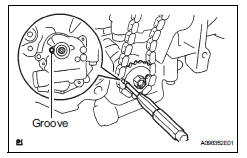

- Turn the crankshaft by 90° counterclockwise to align the adjusting hole of the oil pump drive shaft sprocket with the groove of the oil pump.

- Insert a 4 mm diameter bar into the adjusting hole of the oil pump drive shaft sprocket to lock the gear in position, and then remove the nut.

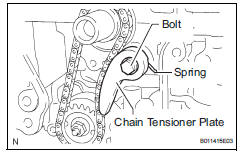

- Remove the bolt, chain tensioner plate and spring.

- Remove the oil pump drive sprocket, oil pump drive shaft sprocket and no. 2 Chain.

Components

Components

...

Inspection

Inspection

Inspect no. 1 Chain tensioner

Check that the plunger moves smoothly when the

ratchet pawl is raised with your finger.

Release the ratchet pawl, then check that the

plunger is locked ...

Other materials:

Air conditioning filter

The air conditioning filter must be changed regularly to maintain

air conditioning efficiency.

Removal method

Vehicles without a smart key system: turn the engine switch to the

“lock” position.

Vehicles with a smart key system: turn the engine switch off.

Open the glove box. Slide ...

Removal (2006/01- )

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove roof headlining assembly

Remove the roof headlining (see page ir ...

When towing active torque control 4wd vehicles

Use one of the methods shown below to tow the

vehicle.

If the vehicle has trouble in the chassis and drivetrain,

use method 1 (flat bed truck).

Notice:

Do not use any towing method other than those

shown above.

For example, the towing methods shown below are

dangerous or dama ...