Toyota RAV4 (XA40) 2013-2018 Service Manual: Inspection

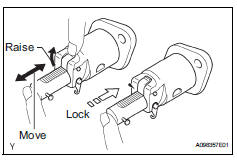

- Inspect no. 1 Chain tensioner

- Check that the plunger moves smoothly when the ratchet pawl is raised with your finger.

- Release the ratchet pawl, then check that the plunger is locked in place by the ratchet pawl and does not move when pushed with your finger.

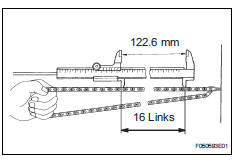

- Inspect chain sub-assembly

- Using a vernier caliper, measure the length of the 16 links with the chain fully stretched.

Maximum chain elongation: 122.6 Mm (4.827 In.)

If the chain elongation is greater than the maximum, replace the chain sub-assembly.

Hint:

Take the measurements at 3 or more places selected at random.

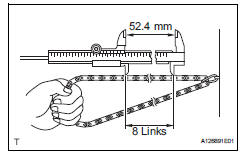

- Inspect no. 2 Chain sub-assembly

- Using a vernier caliper, measure the length of the 8 links with the chain fully stretched.

Maximum chain elongation: 52.4 Mm (2.063 In.)

If the chain elongation is greater than the maximum, replace the no. 2 Chain sub-assembly.

Hint:

Take the measurements at 3 or more places selected at random.

- Inspect chain tensioner slipper

- Using a vernier caliper, measure the tensioner slipper wear.

Maximum wear: 1.0 Mm (0.039 In.)

If the wear is greater than the maximum, replace the chain tensioner slipper.

- Inspect no. 1 Chain vibration damper

- Using a vernier caliper, measure the vibration damper wear.

Maximum wear: 1.0 Mm (0.039 In.)

If the wear is greater than the maximum, replace the no. 1 Chain vibration damper.

- Inspect crankshaft timing sprocket

- Wrap the chain around the timing sprocket.

- Using a vernier caliper, measure the timing gear diameter with the chain.

Minimum gear diameter (with chain): 51.6 Mm (2.031 In.)

Notice:

The vernier caliper must be in contact with the chain rollers when measuring.

If the gear diameter is less than the minimum, replace the chain sub-assembly and crankshaft timing sprocket.

- Inspect oil pump drive sprocket

- Wrap the chain around the drive sprocket.

- Using a vernier caliper, measure the drive gear diameter with the chain.

Minimum gear diameter (with chain): 48.2 Mm (1.898 In.)

Notice:

The vernier caliper must be in contact with the chain rollers when measuring.

If the gear diameter is less than the minimum, replace the no. 2 Chain sub-assembly and oil pump drive sprocket.

- Inspect oil pump drive shaft sprocket

- Wrap the chain around the drive shaft sprocket.

- Using a vernier caliper, measure the drive shaft gear diameter with the chain.

Minimum gear diameter (with chain): 48.2 Mm (1.898 In.)

Notice:

The vernier caliper must be in contact with the chain rollers when measuring.

If the gear diameter is less than the minimum, replace the no. 2 Chain sub-assembly and oil pump drive shaft sprocket.

Removal

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt preten ...

Replacement

Replacement

Replace timing chain cover oil seal

Using a screwdriver and hammer, tap out the oil

seal.

Place the oil seal retainer on wooden blocks.

Apply multi-purpose grease to the lip of a ne ...

Other materials:

Terminals of ecm

Hint:

The standard normal voltage between each pair of ecm

terminals is shown in the table below. The appropriate

conditions for checking each pair of terminals are also

indicated. The result of checks should be compared with the

standard normal voltage for that pair of terminals, displayed ...

For vehicles equipped with catalytic converter caution:

If a large amount of unburned gasoline or gasoline

vapors flow into the converter, it may cause

overheating and create a fire hazard. To prevent this,

observe the following precautions.

Use only unleaded gasoline.

Avoid idling the engine for more than 20 minutes.

Avoid performing unnecess ...

Checking the coolant

The coolant level is satisfactory

if it is between the "FULL" and

"LOW" lines on the reservoir

when the engine is cold.

Reservoir cap

"FULL" line

"LOW" line

If the level is on or below the "LOW" line, add coolant up to the "FULL"

line.

â– Coolant selection

Only use "Toyota Super Long Life

Cool ...