Toyota RAV4 (XA40) 2013-2018 Service Manual: Inspection

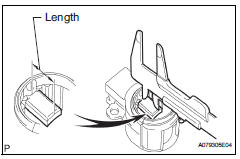

- Inspect generator brush holder assembly

- Using a vernier caliper, measure the brush length.

Standard length: 9.5 To 11.5 Mm (0.374 To 0.453 In.)

Minimum length: 4.5 Mm (0.177 In.)

If the brush length is less than the minimum, replace the generator brush holder assembly.

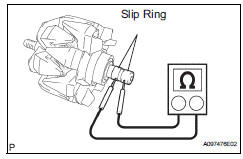

- Inspect generator rotor assembly

- Check the resistance.

- Measure the resistance between the slip rings.

Standard resistance: 2.3 To 2.7 ٠at 20°c (68°f)

If the result is not as specified, replace the generator rotor assembly.

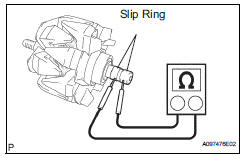

- Measure the resistance between the slip ring and rotor core.

Standard resistance:

1 m or higher

or higher

If the result is not as specified, replace the generator rotor assembly.

- Check the slip ring diameter.

- Using a vernier caliper, measure the slip ring diameter.

Standard diameter: 14.2 To 14.4 Mm (0.559 To 0.567 In.)

Minimum diameter: 14 mm (0.551 In.)

If the diameter is less than the minimum, replace the generator rotor assembly.

- Check the appearance.

- Check that the bearing is not rough or worn.

Ok: the bearing rotates smoothly.

If the result is not as specified, replace the generator rotor assembly.

- Inspect generator drive end frame bearing

- Check that the bearing is not rough or worn.

Ok: the bearing rotates smoothly.

If the bearing does not rotate smoothly, replace the bearing.

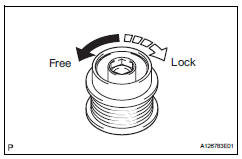

- Inspect generator pulley with clutch

- Hold the center of the pulley, and confirm that the

outer ring turns counterclockwise and does not turn

clockwise.

If the result is not as specified, replace the generator pulley with clutch.

Disassembly

Disassembly

Remove generator pulley with clutch

Remove the cap from the pulley.

Using a screwdriver, puncture the center of the

cap and pry it off.

Notice:

Do not reuse the cap.

Insta ...

Replacement

Replacement

Replace generator drive end frame bearing

Remove the 4 screws and bearing retainer.

Using sst and a hammer, tap out the bearing.

Sst 09950-60010 (09951-00250), 09950-70010

(0995 ...

Other materials:

Cargo and luggage

Take notice of the following

information about storage

precautions, cargo capacity

and load.

WARNING

â– Things that must not be carried

in the luggage compartment

The following things may cause a

fire if loaded in the luggage compartment:

Receptacles containing gasoline

Aerosol cans

â– Storage p ...

Installation

Install no. 2 Chain sub-assembly

Set the crankshaft key in the left horizontal position.

Turn the cutout of the drive shaft so that it faces

upward.

Align the yellow mark links with the timing marks of

each gear as shown in the illustration.

Install the sprockets onto ...

How to proceed with troubleshooting

Hint:

Use the procedure to troubleshoot the power door lock

control system.

*: Use the intelligent tester.

Vehicle brought to workshop

Inspect battery voltage

Standard voltage:

11 to 14 v

If the voltage is below 11 v, recharge or replace the battery

before proceeding.

...