Toyota RAV4 (XA40) 2013-2018 Service Manual: Inspection

- Inspect automatic transaxle oil panel sub-assembly

- Remove the magnets and use them to collect any

steel chips. Examine the chips and particles in the

pan and on the magnet to determine what type of

wear has occurred in the transaxle.

Steel (magnetic): bearing gear and plate wear brass (non-magnetic): bush wear

- Inspect input shaft end play

- Using a dial indicator, measure the input shaft end play.

Standard end play: 0.262 To 1.249 Mm (0.0103 To 0.0492 In.)

- Inspect multiple disc clutch hub

- Using a caliper gauge, measure the inside diameter of the forward clutch hub bushing.

Standard inside diameter: 23.025 To 23.045 Mm (0.9065 To 0.9073 In.)

Maximum inside diameter: 23.09 Mm (0.9091 In.)

Notice:

- When the diameter is over the maximum, replace the multiple disc clutch hub with a new one.

- Check the contact surface of the bush in the direct clutch shaft. If any scratch or discolor is identified, replace the direct clutch subassembly with a new one.

If the inside diameter is greater then the maximum, replace the forward clutch hub.

- Inspect no. 2 Underdrive clutch disc

- Check to see if the sliding surface of the disc, plate

and flange are worn or burnt.

If necessary, replace them.

Notice:

- If the lining of the disc is peeling off or discolored, or even if a part of the groove is defaced, replace all discs.

- Before assembling new discs, soak them in atf for at least 15 minutes.

- Inspect underdrive brake return spring sub-assembly

- Using a vernier caliper, measure the free length of the spring together with the spring seat.

Standard free length: 14.04 Mm (0.5528 In.)

- Inspect 2nd brake clutch disc

- Check to see if the sliding surface of the disc, plate

and flange are worn or burnt.

If necessary, replace them.

Notice:

- If the lining of the disc is peeling off or discolored, or even if a part of the printed number is defaced, replace all discs.

- Before assembling new discs, soak them in atf for at least 15 minutes.

- Inspect 1st and reverse brake clutch disc

- Check to see if the sliding surface of the disc, plate

and flange are worn or burnt.

If necessary, replace them.

Notice:

- If the lining of the disc is peeling off or discolored, or even if a part of the groove is defaced, replace all discs.

- Before assembling new discs, soak them in atf for at least 15 minutes.

- Inspect 1st and reverse brake return spring sub-assembly

- Using a vernier caliper, measure the free length of the spring together with the spring seat.

Standard free length: 15.51 Mm (0.6106 In.)

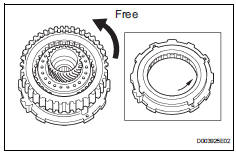

- Inspect underdrive 1-way clutch assembly

- Install the underdrive clutch assembly to the 1-way clutch. Rotate the underdrive clutch assembly to check the rotating direction for the lock or free operation.

Disassembly

Disassembly

Remove park/neutral position switch assembly

Remove the nut, washer and control shaft lever.

Using a screwdriver, pry off the lock plate.

Remove the nut and lock plate.

...

Reassembly

Reassembly

Bearing position

Standard bearing position

Install differential gear lube apply tube

Install the apply tube and clamp to the transaxle

housing with the bolt.

Torque: ...

Other materials:

Fuel information

You must only use unleaded

gasoline in your vehicle.

Select octane rating 87

(Research Octane Number

91) or higher. Use of

unleaded gasoline with an

octane rating lower than 87

may result in engine knocking.

Persistent knocking

can lead to engine damage.

At minimum, the gasoline you

use should meet ...

Engine control system malfunction

Description

If a malfunction in the engine control system is detected, the operations of

vsc and trc are prohibited

by the fail-safe function. When the signals from the engine are input normally,

the fail-safe is canceled and

the dtc is not stored.

Inspection procedure

Check harn ...

Windshield wiper de-icer

This feature is used to prevent ice from building up on the windshield

and wiper blades.

On/off

The windshield wiper de-icer will

automatically turn off after approximately

15 minutes. Pressing the

switch again also turns the de-icer

off.

Operating conditions

Vehicles without a smart ...