Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation

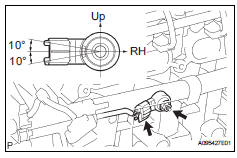

- Install knock sensor

- Install the sensor with the nut.

Torque: 20 n*m (205 kgf*cm, 15 ft.*Lbf)

Notice:

Make sure that the knock sensor is in the correct position.

- Connect the sensor connector.

- Install intake manifold insulator

- install the intake manifold insulator onto the cylinder block.

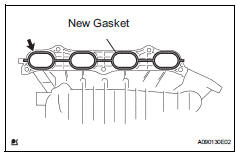

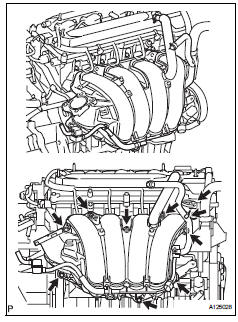

- Install intake manifold

- Install a new gasket into the intake manifold.

- Install the intake manifold with the 5 bolts and 2 nuts.

Torque: 30 n*m (305 kgf*cm, 22 ft.*Lbf)

- Fit the union to check valve hose into the vacuum hose clamp.

- Install the wire harness clamp.

- Connect the camshaft timing oil control valve connector.

- Connect the union to check valve hose to the brake booster.

- Connect heater water outlet hose

- Install the heater water outlet hose to the water bypass pipe and heater radiator unit.

- Connect heater water inlet hose

- Install the heater water inlet hose to the cylinder head and heater radiator unit.

- Install the hose clamp.

- Install fuel tube

- Install fuel delivery pipe (see page fu-13)

- Install throttle body (see page es-413)

- Install air cleaner cap (see page es-413)

- Connect cable to negative battery terminal

- Add engine coolant (see page co-6)

- Check for engine coolant leakage (see page co-1)

- Check for fuel leakage (see page fu-14)

- Install no. 1 Engine cover (see page es-414)

Inspection

Inspection

Inspect knock sensor

Measure the resistance of the sensor.

Standard resistance

If the result is not as specified, replace the knock

sensor. ...

Integration relay

Integration relay

On-vehicle inspection

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airb ...

Other materials:

Precaution

Check that the battery cables are connected to the

correct terminals.

Disconnect the battery cables if a quick charge is

given to the battery.

Do not perform tests with a high voltage insulation

resistance tester.

Never disconnect the battery while the engine is

running.

Check tha ...

Components

Fuse boxes

Engine oil filler cap

Engine oil level dipstick

Battery

Brake fluid reservoir

Radiator

Electric cooling fan

Condenser

Washer fluid tank

Engine coolant reservoir

Checking the engine oil

With the engine at operating

temperature and turned off,

check the oil level on the di ...

Rear wiper motor

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove back door center garnish (see page

ed-59)

...