Toyota RAV4 (XA40) 2013-2018 Service Manual: Reassembly

Hint:

Use high-temperature grease to lubricate the bearings, gears, return spring and steel ball when assembling the starter.

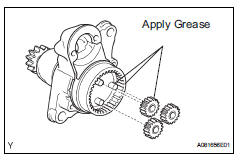

- Install planetary gear

- Apply grease to the planetary gears and pin parts of the planetary shaft.

- Install the 3 planetary gears.

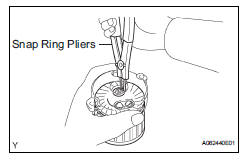

- Install starter armature assembly

- Apply grease to the plate washer and the armature shaft.

- Install the starter armature to the starter commutator end frame.

- Using snap ring pliers, install the plate washer and a new snap ring.

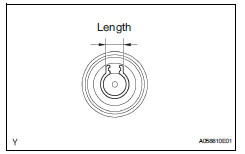

- Using a vernier caliper, measure length of the snap ring.

Maximum length: 5.0 Mm (0.197 In.)

If the length is greater than the maximum, replace it with a new snap ring.

- Install starter commutator end frame cover

- Install the end frame cover to the commutator end frame.

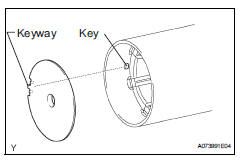

- Install starter armature plate

- Insert the armature plate to the starter yoke.

- Align the keyway of the starter plate with the key inside the starter yoke, and install the starter plate.

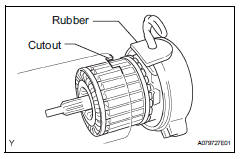

- Install starter commutator end frame assembly

- Align the rubber of the end frame with the cutout of the starter yoke.

- Install the end frame to the starter yoke.

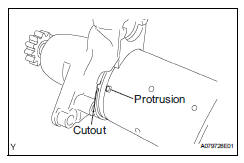

- Install starter yoke assembly

- Align the protrusion of the starter yoke with the cutout of the starter drive housing.

- Install the starter yoke with the 2 through-bolts.

Torque: 5.9 N*m (60 kgf*cm, 52 in.*Lbf)

- Install magnetic switch assembly

- Apply grease to the plunger and the hook.

- Hang the plunger hook of the magnetic switch to the drive lever.

- Install the plunger and return spring.

- Install the magnetic switch with the 2 screws.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*Lbf)

- Connect the lead wire to the magnetic switch with

the nut.

Torque: 10 n*m (102 kgf*cm, 7 ft.*Lbf)

Inspection

Inspection

Inspect starter assembly

Notice:

These tests must be performed within 3 to 5 seconds

to avoid burning out the coil.

Perform the pull-in test.

Disconnect the lead wire from terminal c ...

Installation

Installation

Install starter assembly

Install the starter with the 2 bolts.

Torque: 37 n*m (377 kgf*cm, 27 ft.*Lbf)

Connect the starter connector.

Install the terminal nut and cover the nu ...

Other materials:

Short in front passenger side pretensioner squib circuit

Description

The front passenger side front pretensioner squib circuit consists of the

center airbag sensor and the front

seat outer belt rh.

This circuit instructs the srs to deploy when the deployment conditions are met.

These dtcs are recorded when a malfunction is detected in th ...

Front door lock

Inspection

Inspect front door with motor lock assembly lh

Apply the battery voltage to the motor terminals and

check the operation of the door lock motor.

Ok

If the result is not as specified, replace the door lock

assembly.

Measure the resistance of the door lock position

...

Ecu power source circuit

Description

This is the power source for the tire pressure warning ecu.

Wiring diagram

Inspection procedure

Notice:

It is necessary to register an id code after replacing the tire pressure

monitor valve and/or the tire

pressure warning ecu (see page tw-9).

Inspect fuse (ecu-ig1)

...