Toyota RAV4 (XA40) 2013-2018 Service Manual: Vehicle speed sensor "A"

![]()

description

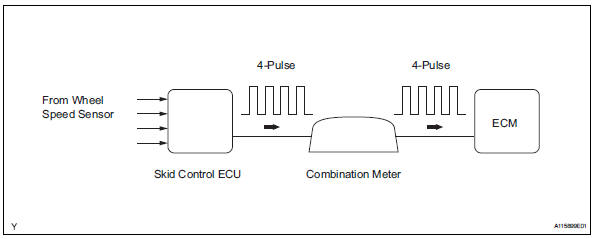

The speed sensor detects the wheel speed and sends the appropriate signals to the skid control ecu.

The skid control ecu converts these wheel speed signals into a 4-pulse signal and outputs it to the ecm via the combination meter. The ecm determines the vehicle speed based on the frequency of these pulse signals.

Monitor description

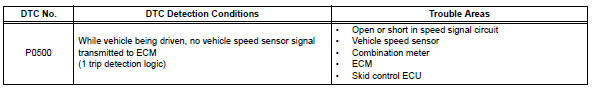

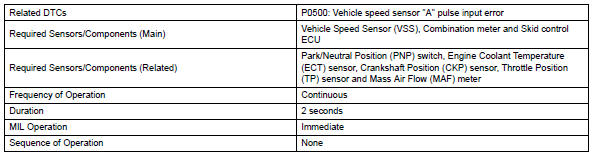

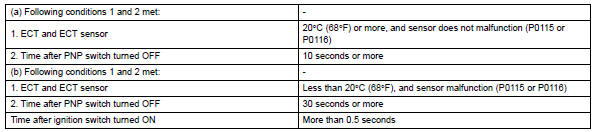

The ecm assumes that the vehicle is being driven, when the indicated engine speed is more than 2,300 rpm and 30 seconds have elapsed since the park/neutral position (pnp) switch was turned off. If there is no speed signal from the combination meter, despite these conditions being met, the ecm interprets this as a malfunction in the speed signal circuit. The ecm then illuminates the mil and sets the dtc.

Monitor strategy

Typical enabling conditions

![]()

Typical malfunction thresholds

![]()

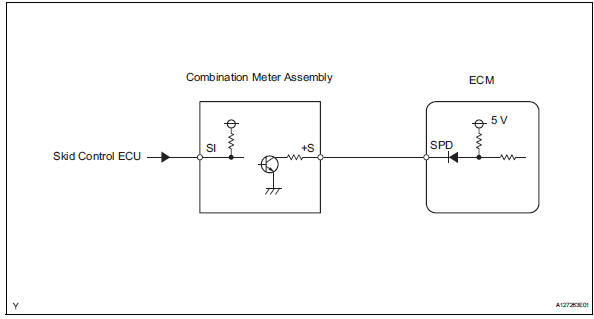

Wiring diagram

Inspection procedure

Hint:

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

- Check operation of speedometer

- Drive the vehicle and check whether the operation of the speedometer in the combination meter is normal.

Hint:

- The vehicle speed sensor is operating normally if the speedometer reading is normal.

- If the speedometer does not operate, check it by following the procedure described in speedometer malfunction (see page me-41).

- Read value using intelligent tester (vehicle spd)

- Connect the intelligent tester to the dlc3.

- Turn the ignition switch on.

- Turn the tester on.

- Select the following menu items: diagnosis / enhanced obd ii / data list / primary / vehicle spd.

- Drive the vehicle.

- Read the value displayed on the tester.

Ok: vehicle speeds displayed on tester and speedometer display are equal.

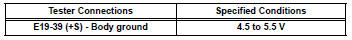

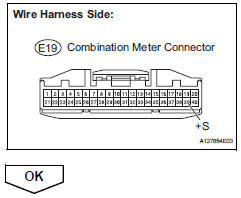

- Check combination meter assembly (+s voltage)

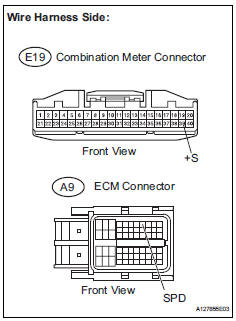

- Disconnect the e19 combination meter connector.

- Turn the ignition switch on.

- Measure the voltage between the terminal of the combination meter and the body ground.

Standard voltage

- Reconnect the combination meter connector.

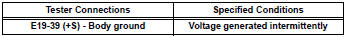

- Check combination meter assembly (spd signal waveform)

- Shift the transmission gear selector lever to the neutral position.

- Jack up the vehicle.

- Turn the ignition switch on.

- Check the voltage between the terminal of the combination meter and the body ground while the wheel is turned slowly.

Standard voltage

Hint:

The output voltage should fluctuate up and down, similarly to the diagram, when the wheel is turned slowly.

- Check harness and connector (combination meter assembly - ecm)

- Disconnect the e19 combination meter connector.

- Disconnect the a9 ecm connector.

- Check the resistance.

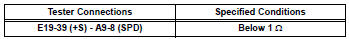

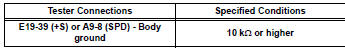

Standard resistance (check for open)

Standard resistance (check for short)

- Reconnect the combination meter connector.

- Reconnect the ecm connector.

Evaporative emission control system leak detected

Evaporative emission control system leak detected

Dtc summary

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monito ...

Brake switch "A" / "B" correlation

Brake switch "A" / "B" correlation

Description

The stop light switch is a duplex system that transmits two signals: stp and

st1-. These two signals are

used by the ecm to monitor whether or not the brake system is working prope ...

Other materials:

Parking brake

Sets the parking brake

Fully pull the parking brake while

depressing the brake pedal.

Releases the parking brake

Slightly raise the lever and lower it

completely while pressing the button.

Usage in winter time

Notice

Before driving

Fully release the parking brake.

Driving t ...

Shift solenoid "d" control circuit

Description

Shifting from 1st to o/d is performed in combination with the on and off

operation of the shift solenoid

valves sl1 and sl2, which are controlled by the ecm. If an open or short circuit

occurs in any of the shift

solenoid valves, the ecm controls the remaining normal shift sol ...

Axle system

Problem symptoms table

Hint:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order th ...